NASA is completing the development of the X-59 Quiet SuperSonic Technology (QueSST) aircraft. It is developed on the basis of next-generation advanced technologies that will be used in commercial aircraft. On December 12, the management gave a green signal to begin the final assembly and integration of its systems after previously completed work was accepted at NASA headquarters in Washington.

According to the schedule, the aircraft should take off in 2021 (the final assembly and integration of all systems should be completed by the end of 2020). It is being built at Lockheed Martin Aeronautics Company’s Skunk Works factory in Palmdale, California, under a $247.5 million cost-plus-incentive-fee contract.

After completion of the construction, the experimental aircraft will be able to fly at a cruise altitude of approximately 17,000 meters at a speed of Mach 1.27 (1,512 km/h). In this case, the noise from it will be only 75 dB. The X-59 QueSST is shaped to reduce the loudness of a sonic boom reaching the ground to that of a gentle thump if it is heard at all.

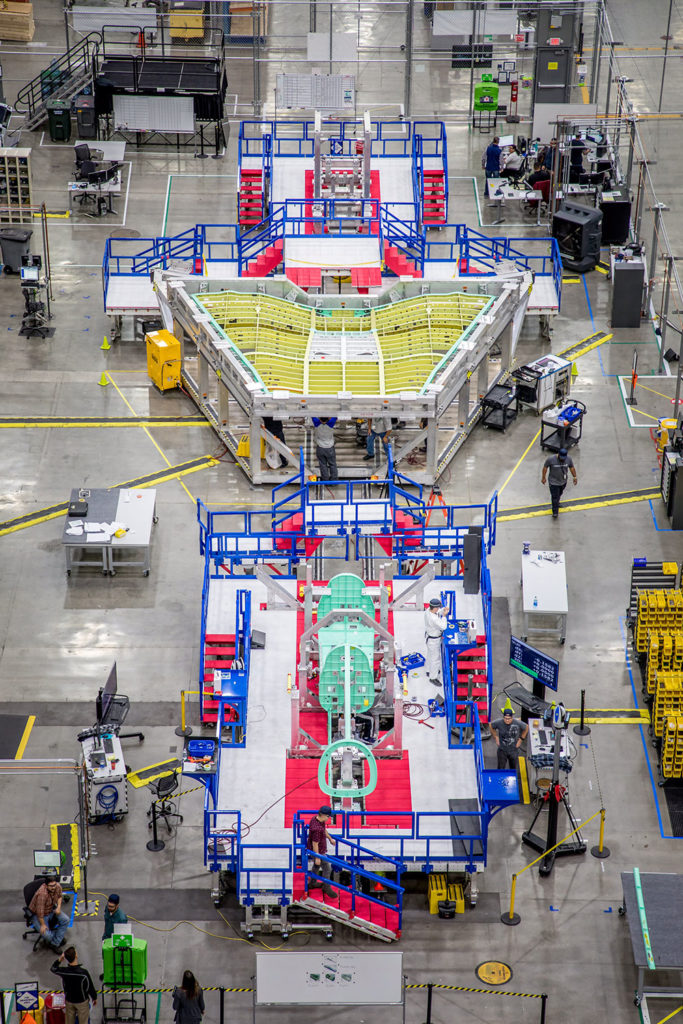

Three main work areas are actively established to build the main fuselage, wing, and empennage of the plane. The final assembly and integration of the aircraft systems, including an innovative cabin external visibility system, is planned for the end of 2020.

The X-59 QueSST will be flown above select U.S. communities to generate data from sensors and people on the ground in order to gauge public perception. Various American manufacturers will be able to collect technical data and analyze the public reaction to this aircraft. That data will help regulators establish new rules to enable commercial supersonic air travel overland.