Operating airplanes during winter conditions can be very challenging. Ice formation on the surfaces is responsible for flight delays and fatal accidents. This is why removing ice, frost, or snow is obviously a requirement for safe airplane operations during winters. Above-ground de-icing is usually accomplished by spraying the aircraft with thousands of gallons of de-icing fluid. But most of this liquid is simply washed off the surface of the aircraft as it takes off, ending up in freshwater streams and lakes and polluting the environment.

To address these problems, two researchers from the University of Illinois Chicago (UIC) have come up with a longer-lasting alternative to conventional de-icers. They have developed an extensive family of more than 80 bio-friendly coatings immune to ice.

De-icing fluids typically consist of either ethylene or propylene glycol-based fluids containing water, corrosion inhibitors, wetting agents, and dye to protect the metal surface. But glycols dissolve very fast in the water and get washed away before the plane takes off, most of which literally ends up in the drain. Thus, they provide limited protection against the formation of further frost and ice or the accumulation of snow on the surfaces.

The new anti-freezing coatings – in the form of mixtures, non-aqueous emulsions-creams, and gels – are designed to withstand the shearing forces of take-off and are also biofriendly if they do wash into waterways.

“Our coatings are an all-in-one package which can delay formation of frost for extended hours and simultaneously cause any ice formed on its surface to easily shed off by a gentle breeze or simple substrate tilting,” said Rukmava Chatterjee, a UIC Ph.D. student, who worked on this research.

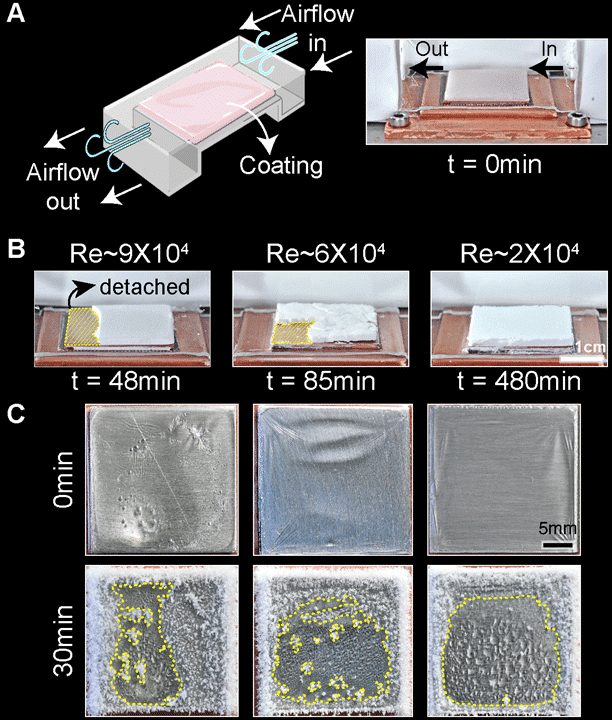

The anti-freezing coatings are a family of phase change material-based formulations and multifunctional coatings, which can tailor solid foulant adhesion on functional surfaces. The layer protects the underlying substrate from a variety of foulants, varying from ice to disease-causing bacteria, irrespective of their inherent material structure and chemistry. The formulations were engineered by regulating how chemicals leach out of the material system and by creating a lubricating surface layer that is both slippery and non-freezing in nature.

Each formulation utilizes unique chemistry to curtail the embodied cryoprotectant loss. They can be easily applied to aluminum, steel, copper, glass, plastic, or any industrial surface without preconditioning or expensive surface treatments. These slurry-like solutions are also transparent at room temperature, making them suitable for applications like traffic signals, runway lights that assist pilots during landings, automotive windshields, or building windows.

“Imagine coating your smartwatch with our gel that can inhibit ice accretion in the chilly negatives while simultaneously preventing any bacterial contamination,” Chatterjee said.

In addition to the obvious applications in transport and buildings, the UIC engineers also believe there is a potential to use their anti-icing sprays in agriculture to prevent crops from being ruined by severe frost. However, more research would be required to see if there will be any long-term adverse effects on the plants.

“There is great potential in these materials for many applications, and I think the day when commercial versions of our materials come out just got closer,” said Sushant Anand, UIC assistant professor of mechanical engineering.