Steel is one of the most widely used materials in a range of industrial environments due to its various advantages, such as its excellent mechanical properties and reasonable costs. However, its low corrosion resistance limits the life of the equipment and hinders certain applications such as shipping and implementation of marine technologies.

Now, researchers from the Korea National Ocean and Maritime University (KMOU) have developed a new aluminum-magnesium-silicon (Al-Mg-Si) alloy that can greatly increase the corrosion resistance of steel by adding a simple extra step in the surface treatment.

Steel is often coated in other metals such as aluminum (Al) to improve its corrosion resistance. But the use of Al in marine applications is limited owing to its tendency to react with chloride ions in seawater, leading to corrosion.

So for the new study, KMOU engineers added other elements in aluminum, such as magnesium (Mg) and silicon (Si), to form an alloyed coating is a promising way around this problem. But Mg cannot be easily deposited as a coating using the conventional method of dipping the steel into a hot bath of metal salts.

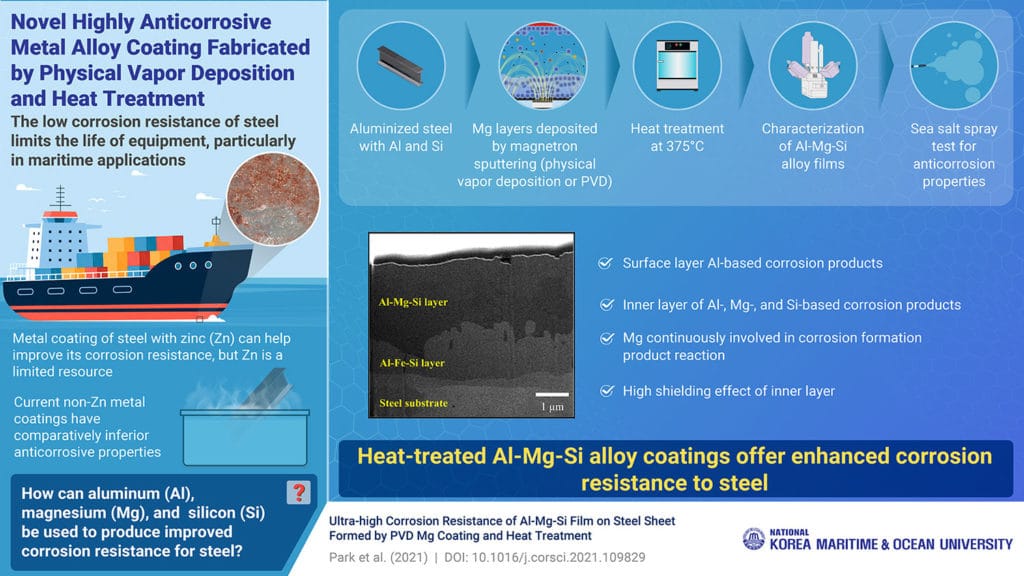

Researchers first took aluminized steel (with Al and Si) and then plated it with Mg using a technique called physical vapor deposition. Finally, the coating was then exposed to a high temperature of 375 °C, for different amounts of time. They then characterized the coating film and performed corrosion testing in the form of a salt spray test.

They found that the corrosion products were also formed in two layers: a surface layer made of primarily Al-based corrosion products and an inner corrosion layer made of Al-, Mg-, and Si-based products. Moreover, the inner layer of corrosion products produced a “shielding effect,” which further improved their anti-corrosion properties.

“Our research reveals how highly corrosion-resistant steel can be produced using a simple change in the surface treatment protocol. This makes it very meaningful for conserving energy and environmental resources,” explains Professor Myeong-Hoon Lee of the Korea National Maritime and Ocean University, who guided the study.