Managing the growing carbon waste from face masks is critical to stemming the tide of planetary desecration. Face masks, be they disposable or reusable, have been the subject of many discussions worldwide from the onset of the COVID-19 pandemic.

Scientists and inventors around the world are finding different solutions to tackle this problem. Some of the solutions are using these discarded face masks to create stronger, more durable concrete, to make eco-friendly bricks, and to develop flexible, low-cost batteries.

Now, the researchers at Swansea University have pioneered a process that transforms these used face masks into Ethernet cables.

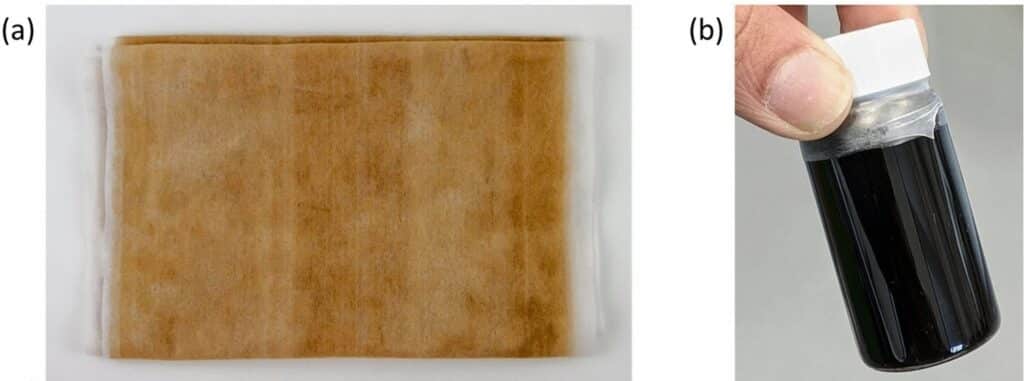

This green chemistry converts the carbon found in discarded face masks to create high-quality single-walled carbon nanotubes (CNT), which were then used to make Ethernet cables with broadband quality. The new process could be used to upcycle materials, which would otherwise be thrown away, and transform them into high-value materials with real-world applications.

The CNTs produced by this technique have the potential not only to be used in Ethernet cables but also in the production of lightweight batteries used in electric cars and drones.

“Single-use facemasks are a real travesty for the recycling system as they create vast amounts of plastic waste – much of it ending up in our oceans. During the study, we established that the carbon inside the facemask could be used as a pretty good feedstock to make high-quality materials like CNTs,” said Professor Alvin Orbaek White of Swansea University’s Energy Safety Research Institute (ESRI).

“CNTs are highly sought-after because they have preferential physical properties and tend to be much more costly on an industrial scale. So, through this study, we demonstrated that we could make very high-value materials by processing the CNTs from what are, essentially, worthless waste facemasks.”

The researchers also studied the energy costs involved in using this process and concluded that the technique was green not only in levels of resource consumption but also in product value generation as opposed to waste creation. Also, the Ethernet cable produced using the CNTs was good quality and adhered to Category 5 transmission speeds while easily exceeding the benchmarks set for broadband internet in most countries.

“Using CNT films in batteries instead of metal films has a lower impact on the environment as the use of carbon offsets the need for mining and extraction activities,” said Professor Orbaek White. “This is a crucial piece of work as it contributes to not only a circular economy but is also scalable and is viable for industrial processing and has green chemistry at its core.”

Journal reference:

- Varun Shenoy Gangoli, Thomas Mahy, Tim Yick, Yubiao Niu, Richard E. Palmer, and Alvin Orbaek White. Upcycling of face masks to application-rich multi- and single-walled carbon nanotubes. Carbon Letters, 2022; DOI: 10.1007/s42823-022-00398-8