Biodegradable plastics are commonly used for disposable items, such as packaging, crockery, cutlery, and foodservice containers. These plastics are specifically designed to degrade quickly and therefore traditionally can’t be recycled. But an even better solution for the environment will be if even these plastics can be reused or recycled.

Researchers from the University of Canterbury in New Zealand have developed a method to turn biodegradable plastic knives, spoons, and forks into foam that can be used as insulation in walls or flotation devices.

Researchers placed the cutlery, which was previously thought to be “nonfoamable” plastic, into a chamber where carbon dioxide was dissolved into the plastic at high pressure. When they suddenly released the pressure in the chamber, the carbon dioxide expanded within the plastic, creating foaming – just like opening a can of soda and releasing the carbonation.

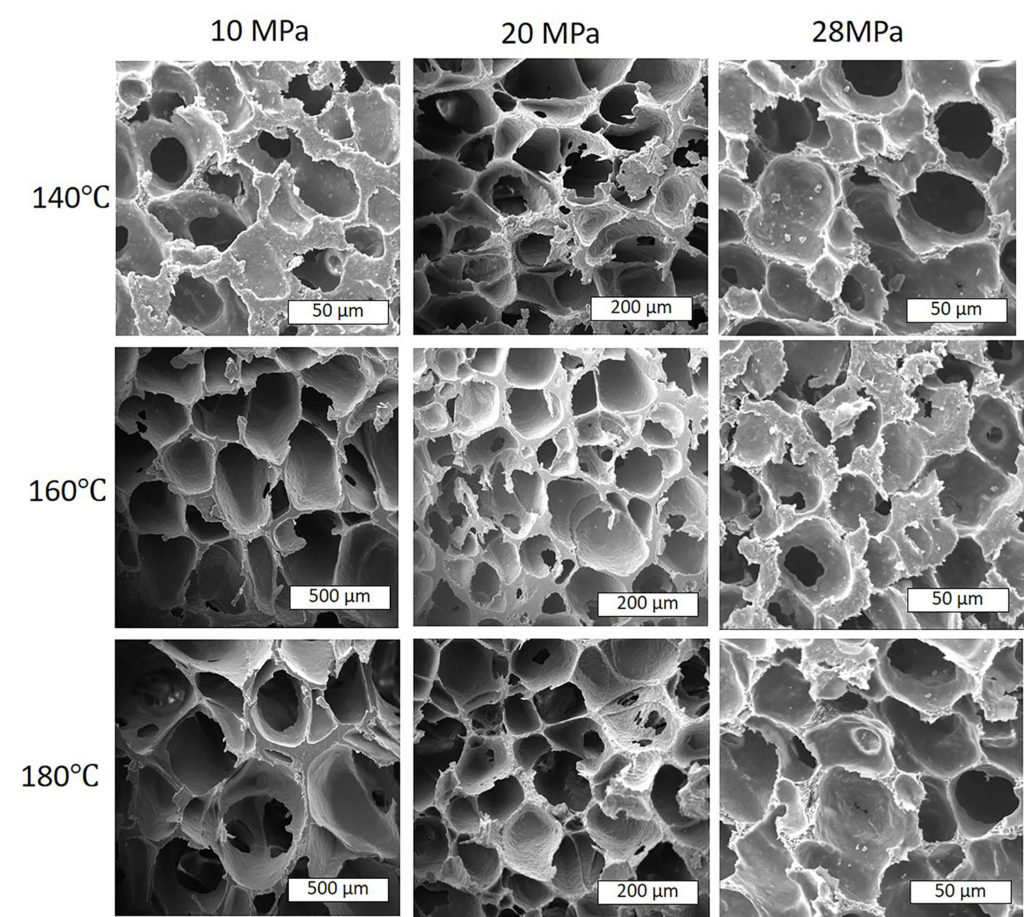

“Tweaking temperature and pressure, there is a window where we can make good foams,” said Park. “It’s not that every temperature or every pressure works. We found what temperature or what pressure is the best to make those nonfoamable plastics into foams.“

Each time plastic is recycled, it loses a bit of its strength, and since biodegradable plastic is meant to decompose, it doesn’t offer a lot of structural integrity, to begin with. A new fork made out of a recycled, biodegradable fork might not be strong enough to pick up solid food, or it may break in your mouth.

Foams, though, don’t require to be as strong as solid plastics in many applications. Also, there’s no need to worry about foams made of biodegradable plastic breaking down when they’re used.

The ideal structure of foam depends on its final use. Bulky foams, which have large or plentiful air pockets, are good for buoys. The researchers found the lower chamber pressures led to bulky foams.

Converting biodegradable plastics into recyclable materials could alleviate some of the global pollution problems. While biodegradable material eventually breaks down in nature, it is even better for the environment if plastics can be repurposed.

This way, the biodegradable and recyclable plastics can be used more than once but are also less of an environmental threat if they end up in oceans or landfills. Researchers believe this process could be implemented on a large scale.

“We can expand foaming applications to a lot of plastics, not just this plastic,” said author Heon Park.