Micro-combined heat and power (mCHP) systems are an innovative solution for energy-efficient homes and buildings. These systems generate heat and electricity simultaneously from a single source, such as natural gas, and can significantly reduce energy costs and carbon emissions.

Now, Oak Ridge National Laboratory researchers, in collaboration with Enginuity Power Systems, demonstrated that an mCHP prototype powered by innovative inwardly opposed-piston engine technology could achieve an overall energy efficiency greater than 93%. Designed to replace a backup generator or traditional gas hot water heater, the environmentally friendly mCHP switches between natural gas, hydrogen, or biogas and combines battery storage and solar energy.

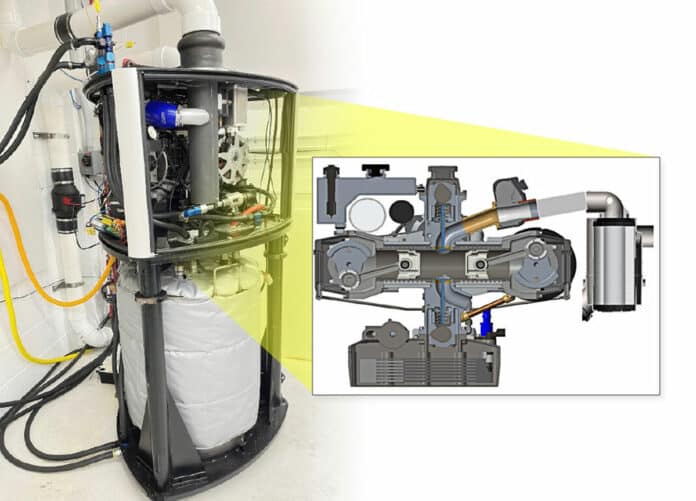

Researchers evaluated an mCHP prototype that uses a four-stroke opposed piston (OP4S) engine. The OP4S engine can run on multiple fuels, including renewable gas (biogas), natural gas, and propane, as well as hydrogen, to generate mechanical power and waste heat in the form of hot coolant and exhaust gas simultaneously. The waste heat is recovered and stored in the 52-gal water tank and can be used as a regular hot water supply and for space heating applications.

It’s environmentally friendly and cost-effective because the heat that would otherwise be wasted is captured and reused to provide thermal energy at a small scale for a building in a single process. This allows for a higher efficiency compared to conventional equipment that serves only one function.

During the demonstration, the mCHP prototype enabled power outputs in the range of 3.2 -7.4 kW with up to 26.4% of AC electricity efficiency and up to 93.1% of the overall mCHP efficiency under stoichiometric combustion modes. Furthermore, the 24-hour operation under the stoichiometric mode did not degrade any performance of the mCHP, indicating the good potential of the prototype’s reliability and durability.

The mCHP was also run under lean combustion mode conditions, which enabled more than a 30% improvement in electrical energy efficiency. The maximum AC efficiency of the lean combustion mode attained was 35.2%, with the engine efficiency approaching 40%.

The mCHP prototype can achieve low-cost, flexible matching of thermal and electrical loads by reducing the complexity of distribution and installation, along with high efficiency and its ability to use a variety of fuels, including biogas and hydrogen. The novel technology is expected to promote mCHP acceptance and accelerate the adoption of mCHP in small residential and commercial buildings for remote and underserved communities.

Journal reference:

- Gao, Zhiming; Zoldak, Philip; Mansinger, Jonathan; De maria, Joseph; Mannarino, Tony; Beaudry losique, Jacques; Nawaz, Kashif; Zhang, Mingkan; Abuheiba, Ahmad; Cheekatamarla, Praveen; Edwards, Dean. Development and testing of residential micro-CHP powered by opposed piston engine, 2023; DOI: 10.2172/1963144