Battery storage, especially powerful lithium-ion devices, are defined as greener and cleaner energy storage devices due to their higher voltage, high energy density. However, these devices have their drawbacks, as the extraction practices and cost of lithium have raised concerns.

Now, a Chinese giant CATL (Contemporary Amperex Technology) has unveiled its first-generation sodium-ion battery that could “provide a new solution for the use of clean energy and transportation electrification.” The manufacturer claims that its first-generation sodium-ion battery meets all the requirements of modern customers.

The sodium-ion batteries are not new. The concept emerged at a similar time as the lithium-ion batteries, as both types have a similar working principle. Sodium ions also shuttle between the cathode and anode. However, compared with lithium ions, sodium ions have a larger volume and higher requirements regarding structural stability and the kinetic properties of materials. This has become a bottleneck for the industrialization of sodium-ion batteries.

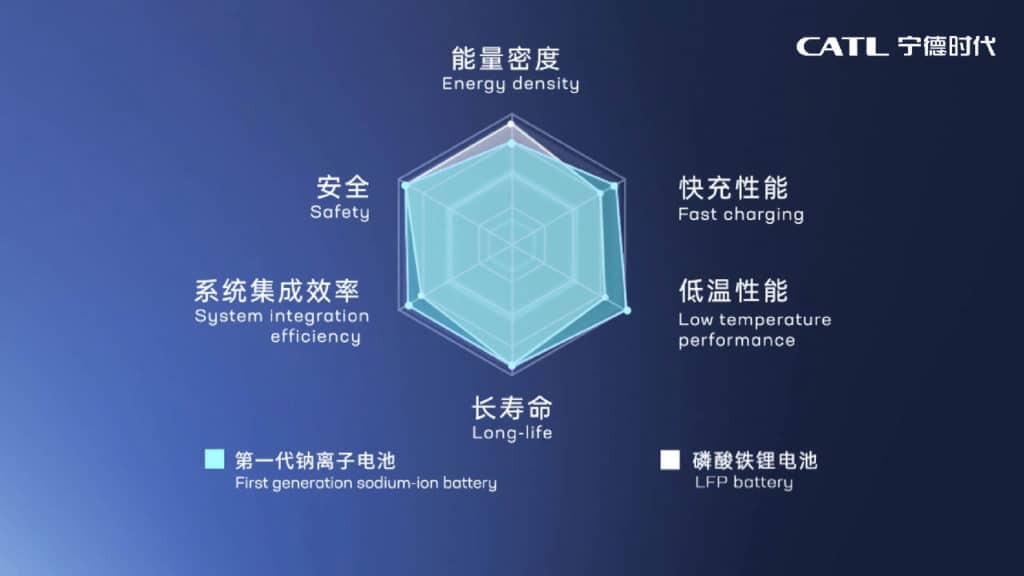

CATL says its researchers have been dedicated to researching and developing sodium-ion battery electrode materials for many years. For the cathode, they used Prussian white material with a higher specific capacity to rearrange the electrons, while a hard carbon material that features a unique porous structure is used for the anode. These form key components of the company’s first commercial sodium-ion battery, which promises to come with “high-energy density, fast-charging capability, excellent thermal stability, great low-temperature performance, and high-integration efficiency.”

CATL’s sodium-ion battery cell is claimed to have an energy density of up to 160 Wh/kg. This figure is slightly lower than the 200 Wh/kg achieved by the LFP devices that CATL distributes for Tesla, but Robin Zeng, president of CATL, has already suggested that they plan the future designs to exceed 200Wh/kg, which is comparable to many lithium-ion batteries.

The battery can charge in 15 minutes to 80% SOC at room temperature. Moreover, in a low-temperature environment of -20 degrees Celsius, the sodium-ion battery has a capacity retention rate of more than 90%, and its system integration efficiency can reach more than 80%.

CATL says its new sodium batteries can be used in various transportation electrification scenarios, especially in regions with extremely low temperatures. Also, it can be flexibly adapted to the application needs of all scenarios in the energy storage field.

It is said that sodium-ion battery manufacturing is perfectly compatible with the lithium-ion battery production equipment and processes, and the production lines can be rapidly switched to achieve a high production capacity. As of now, CATL has started its industrial deployment of sodium-ion batteries and plans to form a basic industrial chain by 2023. CATL invites upstream suppliers and downstream customers, as well as research institutions, to jointly accelerate the promotion and development of sodium-ion batteries.