Tamarind fruits are consumed worldwide, and their seeds have an underexploited potential. However, the bulky tamarind shells are discarded during food production and take up a considerable amount of space in landfills, where they are disposed of as agricultural waste.

Now, a team of scientists led by Nanyang Technological University, Singapore (NTU Singapore) has converted the tamarind shells into carbon nanosheets. These carbon nanosheets are a key component of supercapacitors – energy storage devices that are used in automobiles, buses, electric vehicles, trains, and elevators.

The project also involved researchers from the Western Norway University of Applied Sciences and Alagappa University in India. They believe that these nanosheets, when scaled up, could be an eco-friendly alternative to their industrially produced counterparts and cut down on waste at the same time.

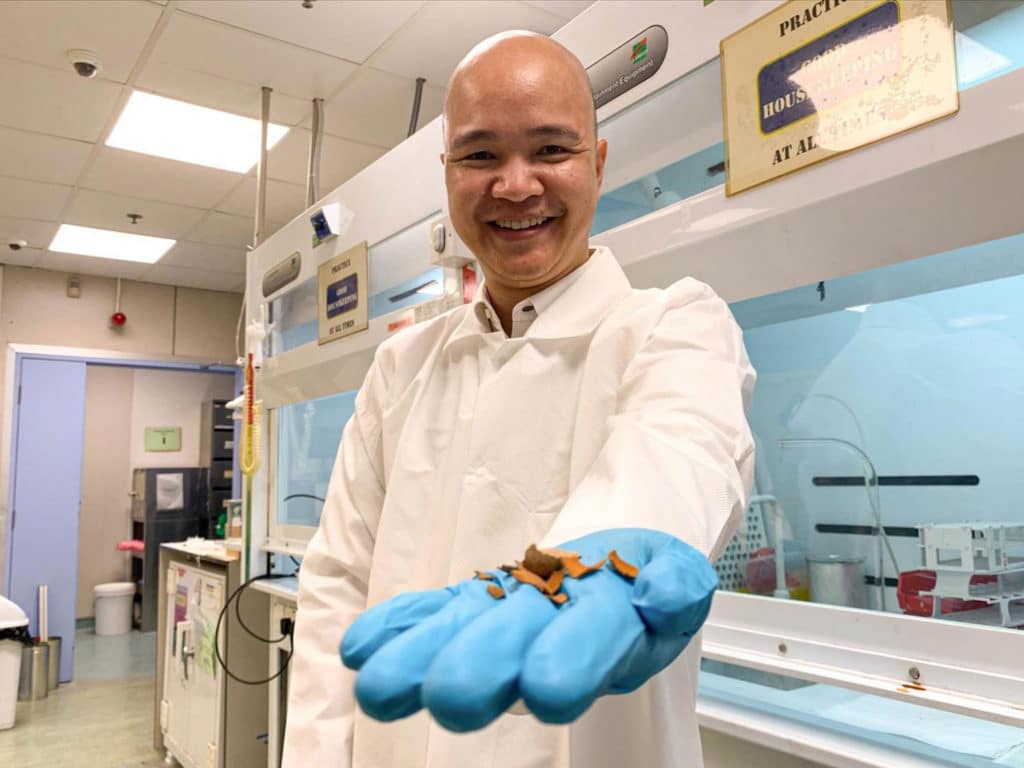

The researchers first washed tamarind fruit shells that were obtained as waste from the food industry and dried them at 100°C for around six hours before grinding them into powder. They then baked the powder in a furnace for 150 minutes at 700-900 degrees Celsius in the absence of oxygen to convert them into ultrathin sheets of carbon known as nanosheets.

Tamarind shells are rich in carbon and porous in structure, making them an ideal material for manufacturing carbon nanosheets. The porosity increases the surface area of the carbon in the nanosheets, allowing it to store large amounts of electric charges.

Additionally, the tamarind shell-derived nanosheets showed good thermal stability and electric conductivity, making them promising options for energy storage.

The researchers are working on reducing the energy needed for the production process, making it more environmentally friendly, and are seeking to improve the electrochemical properties of the nanosheets. They are also hoping to explore the larger-scale production of carbon nanosheets with agricultural partners.