One of the major challenges of the wind energy sector is its impact on the environment once the plants have been dismantled. Disposal of wind turbine blades, which are generally non-biodegradable and non-recyclable products, poses environmental problems when components reach end-of-service-life. This situation is about to change thanks to the CETEC initiative.

In collaboration with Danish Technological Institute, Aarhus University, and the Epoxy products manufacturer Olin, the Danish wind turbine giant Vestas has developed a new technology to enable circularity for thermoset composites, the material used to make wind turbine blades. The new technology is a step towards a fully recyclable wind turbine value chain.

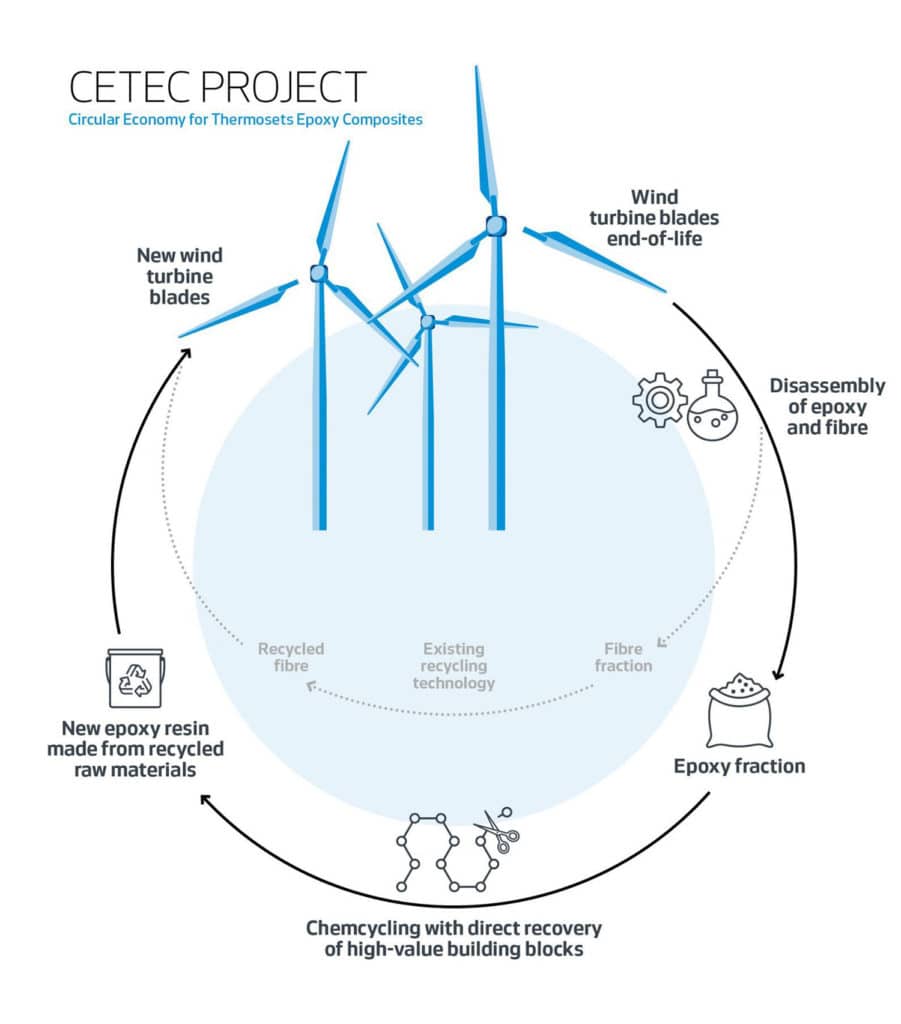

A new initiative entitled CETEC (Circular Economy for Thermosets Epoxy Composites) has been established to enable the adoption of this new technology and advance a circular economy across the wind industry. CETEC is aiming to present a fully scoped solution ready for industrial adoption within three years.

The new technology consists of a two-step process. During the first part, the thermoset composites are disassembled into fiber and epoxy. In the second, through a new chemcycling process, the epoxy resin is further broken up into base components similar to virgin materials, which can then be reintroduced into the manufacturing of new turbine blades, constituting a new circularity pathway for epoxy resin.

“The key characteristic of composite materials is their unique combination of low weight and high strength. This is governed by the strong bonding of two different materials – fiber and epoxy,” said Simon Frølich, Team Manager, Ph.D., Danish Technological Institute. “The dilemma is that this strong bond is also the feature that renders these materials difficult to recycle. Therefore, the development of CETEC’s novel technology, enabling disassembly of the composite at end-of-life, is a gamechanger that will allow us to capture the value represented by each material stream in a new circular value chain.“

For now, wind turbines are 85-90% recyclable, with turbine blade material constituting the remaining percentage that cannot be recycled due to the nature of thermoset composites. The project aims to close this recycling gap and enable a significant step forward in eliminating waste across the wind energy industry.

“Chemcycling of epoxy-based materials would allow deconstructing these highly stable polymer chains into molecular building blocks,” added Prof. Dr. Troels Skrydstrup, Aarhus University. “These building blocks are easily processable and can be utilized to produce new epoxy, which will have the same quality as the original material. Avoiding the loss of valuable molecular complexity in such a way is a highly desirable concept and an important step to sustainable materials.”

The CETEC’s recycling solution is expected to gain commercial traction in markets where regulation around waste management for manufacturing industries is tightening. When fully developed, the solution could also have an impact in other sectors that use thermosetting composites in production, such as automotive and aviation, where there is already increasingly spasmodic attention to circularity, starting – obviously – from batteries.