Automobiles require a wide variety of raw materials for their production, so it would be great if some of them came from renewable, environmentally friendly sources. Researchers at the University of Alicante (UA), in collaboration with dozens of European partners, are turning agricultural waste, which is often discarded, into materials for making car parts.

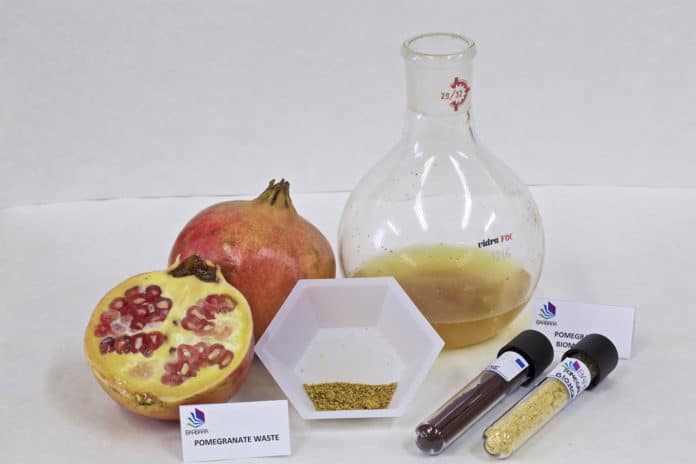

The team has developed high-added-value natural compounds from lemon, pomegranate, broccoli, and almond shells from agricultural waste to replace existing materials in the automotive industry or construction.

From a circular economy approach, researchers have designed more sustainable pieces that help reduce the large amounts of agricultural waste that are generated daily.

The pomegranates, lemons, and broccoli plants have allowed obtaining different colors to be used on the materials that cannot be colored using synthetic dyes. In particular, with the pomegranate, they have found that by changing the pH, a wide range of shades can be obtained.

At the same time, the lemon-derived essential oil has antimicrobial properties and gives off a fresh fragrance. They can be incorporated into items such as sterilizing door handles or cabin deodorant dashboards, while almond bark provides a wood-like appearance and help enhance the mechanical properties of the material.

In the lab, these extracted natural compounds of lemon, pomegranate, broccoli, and almonds have been rolled into filament coils for 3D printing the various automotive parts with improved features and specific aesthetic properties.

This advance has been developed by two UA research groups – the Research Group of Polymers and Nanomaterials Analysis (Nanobiopol) and the Group of Vision and Color – part of the European project Barbara. The project, which aims to develop new bio-based materials with innovative functionalities through fused filament fabrication (3D-printing), began in 2017 and will be completed in April next year. Other project partners have worked with starch residues to obtain more resistant and stronger building materials.