An organized combination of stiff and elastic domains within a single material can synergistically tailor bulk mechanical properties. Now, researchers at The University of Texas at Austin have produced a new plastic-like material, much like many life forms that are hard and rigid in some places and soft and stretchy in others.

According to scientists, the new material needs only light and a catalyst to change properties such as hardness and elasticity in molecules of the same type. Their success has brought about a new material that is ten times as tough as natural rubber and could lead to more flexible electronics and robotics.

In developing the novel material, the scientists drew inspiration from natural materials – such as skin, muscles, trees, and shellfish – that can be rigid in some places and soft and stretchy in others.

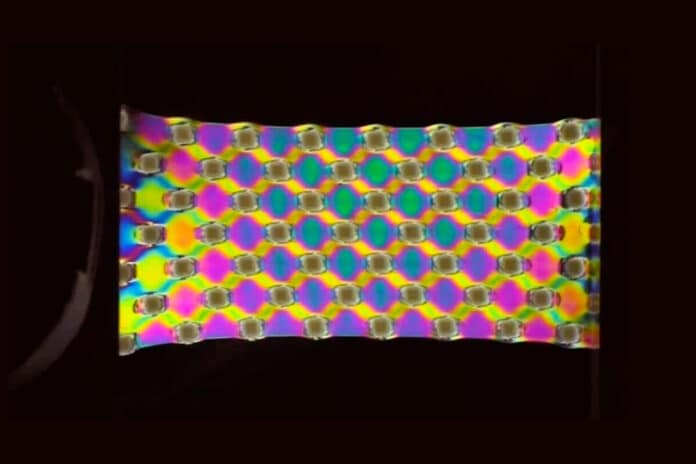

To create the smart plastic, the scientists used a monomer that binds with others like it to form the building blocks for larger structures called polymers that were similar to the polymer found in the most commonly used plastic. After testing several types of catalysts, they found one that could be integrated into the monomers to make them respond to visible light. This had the effect of creating a semi-crystalline polymer similar to those found in existing synthetic rubber, forming a harder and more rigid material. The area not exposed to light, meanwhile, retained its soft, stretchy properties.

“This is the first material of its type,” said Zachariah Page, assistant professor of chemistry and corresponding author on the paper. “The ability to control crystallization, and therefore the physical properties of the material, with the application of light is potentially transformative for wearable electronics or actuators in soft robotics.”

According to the researchers, the experiment can be easily replicated away from laboratories. Both the monomer and the catalyst, used in the manufacture of smart plastic, are commercially available, and researchers used inexpensive blue LEDs as a light source in the experiment. The reaction also takes less than an hour and minimizes the use of any hazardous waste, making the process rapid, inexpensive, energy-efficient, and environmentally benign.

Researchers envision a broad range of applications for their creation, including anchoring electronic components in medical devices or wearable tech and improving the strength and flexibility of robots.

“We are looking forward to exploring methods of applying this chemistry towards making 3D objects containing both hard and soft components,” said first author Adrian Rylski, a doctoral student at UT Austin.

Journal reference:

- Adrian K. Rylski, Henry L. Cater, Keldy S. Mason, Marshall J. Allen, Anthony J. Arrowood, Benny D. Freeman, Gabriel E. Sanoja, Zachariah A. Page. Polymeric multimaterials by photochemical patterning of crystallinity. Science, 2022; DOI: 10.1126/science.add6975