Collaborative robots are safer to work around people than traditional industrial automation. SICK, a sensor maker, has presented its Safe Robotics Area Protection (SRAP) system that, it says, provides process-based protection for collaborative robot applications.

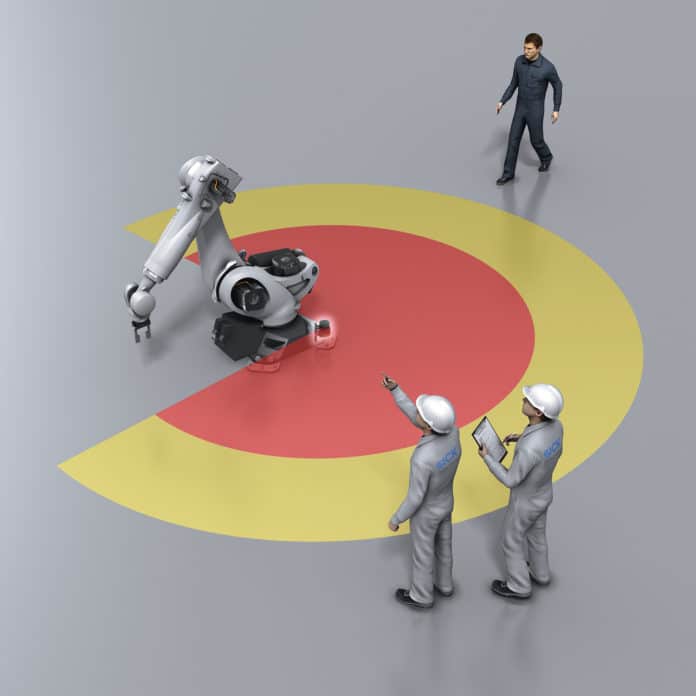

The system allows workers to safely access robot’s working area at any time by adapting the operating conditions to the position of the person. It not only prevents the risk of accidents from occurring but also improves productivity. Besides, it reduces downtime and optimizes the ergonomic and process aspects of the operator’s workflow.

The SRAP system consists of a series of safety systems and products – like a Flexi Soft safety controller and a safety laser scanner – designed especially for cooperative, human-robot applications. Using the tested software function blocks, the safety system can be integrated with ease and fits seamlessly into the controllers of all standard industrial robots.

In addition, the migration capabilities of the system configuration make Safe Robotics Area Protection a future-proof safety system. This enables flexible, autonomous machines, and robots to adapt quickly and effortlessly to new production conditions, safety requirements, and protective field conditions that result from this.

As the safety system detects any worker has entered the robot working area, the sensors cause the robot’s movement to either reduce or stop via the Flexi Soft safety controller. And the system automatically restarts once the person leaves the robot hazard area, or you can implement a manual restart.

It is also claimed that the robot is first started up at a reduced speed and then returns to its original working speed once all the warning and protective fields are free again. In short, the human worker remains completely and constantly protected against hazardous movements whenever they enter the robot’s working area.

SRAP works in a number of different applications and is even suitable for confined space applications. Moreover, the system is very easy to install, just connect the safety devices, select the desired program, and your safety logic is ready to go.

What’s more? If you need other safety devices or additional safety functions, these can be integrated with ease later on – making the SRAP safety system even safer.

“With the increase in collaborative robots, maybe it’s time to re-evaluate how safe your processes are and see how you can help to improve,” the company wrote in a blog post.