Advancements in technology are pushing the boundaries of space exploration. The idea of a ‘self-eating’ rocket engine capable of flight beyond the Earth’s atmosphere sounds like something out of a science fiction movie, but it could have real-world applications in the space industry.

The University of Glasgow engineers have successfully built and fired the first unsupported ‘autophage’ rocket engine, which consumes parts of its own body for fuel. This technology could potentially offer several advantages over conventional rocket designs and could help the UK make a bigger impact in the space industry.

The autophage engine works by using waste heat from combustion to sequentially melt its own plastic fuselage as it fires. The molten plastic is fed into the engine’s combustion chamber as additional fuel to burn alongside its regular liquid propellants.

This means that an autophage vehicle would require less propellant in onboard tanks, freeing up mass for payload allocation. Additionally, the consumption of the fuselage could potentially help address the issue of space debris – discarded waste that orbits the Earth and could hamper future missions.

The greater efficiency could help autophage rockets take a greater payload into space compared to conventional rockets of the same mass. This could mean that smaller nanosatellites could be sent into space without having to share space on more expensive conventionally-fuelled rockets.

The concept of a self-eating rocket engine was first proposed and patented in 1938. However, it wasn’t until 2018 that a research partnership between the University of Glasgow and Dnipro National University in Ukraine achieved the milestone of firing autophage engine designs in a controlled manner.

Now, with support from Kingston University, the Glasgow engineers have demonstrated the use of more energetic liquid propellants and that the plastic fuselage can withstand the forces required to feed it into the engine without buckling. These are essential steps in developing a viable flight concept.

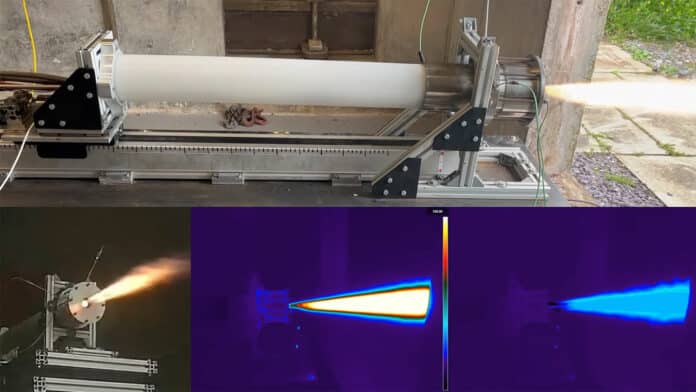

According to the paper, the team was able to successfully conduct test fires of their Ouroborous-3 autophagy engine, which generated 100 newtons of thrust. The experiments were carried out in a controlled environment at the MachLab facility at Machrihanish Airbase.

The Ouroborous-3 engine utilizes high-density polyethylene plastic tubing as its autophagic fuel source, which is burned in combination with the rocket’s primary propellants, which consist of gaseous oxygen and liquid propane.

The test results indicated that the Ouroborous-3 engine is capable of sustaining a stable burn during the autophage stage, which is a crucial requirement for any rocket engine. Additionally, the plastic fuselage was shown to supply up to one-fifth of the total propellant used.

The recent tests also showed that the rocket’s burn could be successfully controlled. Not only was the rocket’s burn throttled effectively, but it was also restarted and pulsed in an on/off pattern. These capabilities could prove useful in helping future autophage rockets control their ascent from the launchpad into orbit.

“These results are a foundational step on the way to developing a fully functional autophage rocket engine,” said Professor Patrick Harkness, who led the development of the Ourouboros-3 autophage engine. “Those future rockets could have a wide range of applications which would help advance the UK’s ambitions to develop as a key player in the space industry.”

“A conventional rocket’s structure makes up between five and 12 percent of its total mass. Our tests show that the Ouroborous-3 can burn a very similar amount of its own structural mass as propellant. If we could make at least some of that mass available for payload instead, it would be a compelling prospect for future rocket designs.”

Development of the team’s autophage engine will continue with the support of new funding from the UK Space Agency (UKSA) and the Sciences and Technology Facilities Council (STFC), part of UK Research and Innovation (UKRI).