A Swiss aerial logistics company RigiTech has unveiled an advanced precision dropping system prototype that revolutionizes the precision and efficiency of deliveries, eliminating the need for landing and takeoff. The system enables fast and precise transportation of parts to offshore wind farms.

The project in Denmark involved the Swiss company partnering with local autonomous systems operator Holo and global transport and logistics company DSV. Using a specialized payload lowering mechanism, the trio went to work testing drone deliveries of replacement parts to offshore wind farms for energy company Ørsted.

The lack of necessary parts during turbine repairs can become costly, as it requires the service vessel to return to shore and back out. This results in a significant time delay and consumes more than 500 liters of diesel fuel.

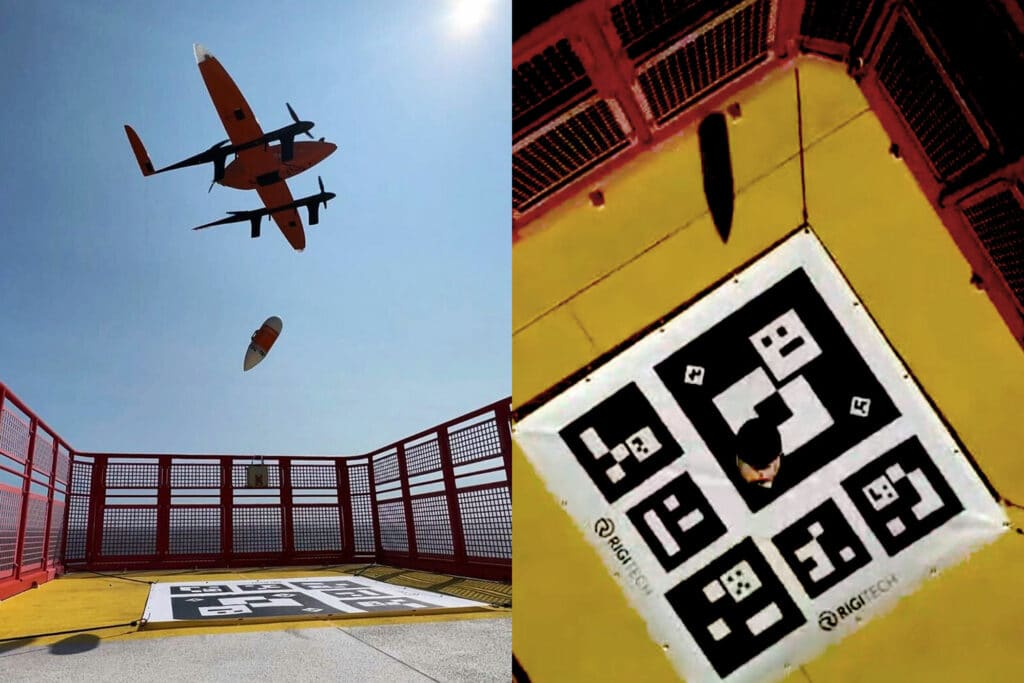

RigiTech’s Eiger UAV (unmanned aerial vehicle) mounted with the dropping system can deliver spare parts to Anholt’s 111 offshore wind turbines within 30 minutes – far faster than usual boat transport. This ensures same-day repair, enhanced safety for on-site technicians, and guarantees minimal turbine downtime.

Integrating drone delivery into existing workflows is possible thanks to RigiCloud and Eiger’s fully autonomous nature. Local warehouse staff loads the spare parts onto the drone, while the Beyond Visual Line of Sight (BVLOS) operations are supervised remotely by Holo in Copenhagen, hundreds of kilometers away. Network-based video streaming from the Eiger provides live monitoring of each delivery to both Holo and Ørsted warehouse staff.

The new cutting-edge dropping system prototype was designed as an optional add-on to the acclaimed Eiger platform. Eiger, the company’s largest drone so far, is configured for nighttime operations and can power through winds up to 15 m/s (54 km/h). It can cover long distances exceeding 62 miles (100 km) and can seamlessly transport goods between cities, reaching even the most remote and challenging locations.

Thanks to the Eiger’s impressive precision target capability, this new precision-dropping system ensures that items are delivered accurately to their intended destinations, streamlining operations and saving valuable time. The prototype add-on is equipped with an automated connector that is remotely and automatically activated by RigiCloud to release the pod once its destination is reached.

Throughout the project, RigiTech and Holo completed a total of 40 flights offshore, with multiple autonomous payload drops on top of the 95 m-high wind turbine located 30 km offshore, with a 100% success rate despite challenging wind conditions.

“This project started with a simple customer challenge: how do we get parts directly to a technician inside a wind turbine?” says Adam Klaptocz, CEO of RigiTech. “The solution was nothing but simple and pushed us to develop multiple cutting-edge technologies, including AI-based flight planning algorithms, precision navigation in high-wind environments, computer vision, and sensor fusion algorithms. The results speak for themselves; spare parts are delivered with cm-level precision, fully autonomously, every time. Available today.”