Accelerating the shift towards renewable materials and sustainable processes for printed organic electronic devices is crucial for a green circular economy. Currently, the fabrication of organic electronics with competitive performances is linked to toxic petrochemical-based solvents with considerable carbon emissions.

By switching the solvents used in their manufacture, organic solar cells could be made much more environmentally sustainable. KAUST (King Abdullah University of Science and Technology) researchers have demonstrated that plant-based solvents can replace today’s non-renewable, environmentally hazardous solvent counterparts without affecting the resulting solar cells‘ light-capturing performance.

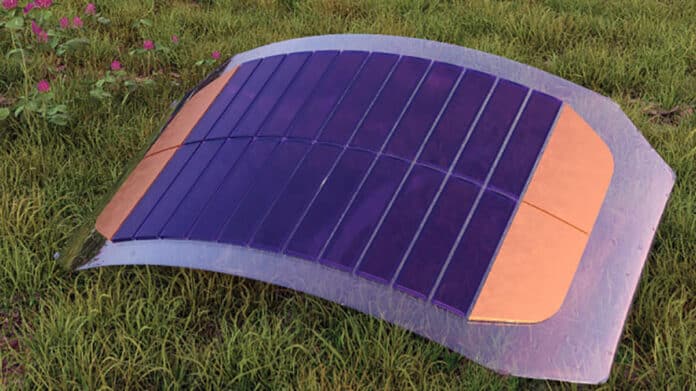

Organic photovoltaics (OPVs) are one of the greenest solar cell technologies, contributing as little as three grams of CO2 equivalent carbon emissions per KW of energy.

“However, their fabrication still relies on halogenated solvents that, on top of being linked to reproductive hazards and cancer, are derived from petrochemical processes,” says Daniel Corzo, a Ph.D. student in Derya Baran’s lab, who led the work. “We wanted to find green alternatives to protect the health and safety of workers when these cells are manufactured at a larger scale and to further reduce the carbon footprint of OPVs.”

Since solvents are the basis of the printable inks used to create organic solar cells, they are critical to OPV manufacture. “These inks require the active organic materials to remain in solution during processing and then crystallize under optimized conditions as the ink dries,” Corzo says. “Solvent choice greatly affects OPV processing and overall device performance.”

Using a Hansen solubility ink formulation framework, researchers identified potential alternative solvents and investigated effective film formation and drying mechanisms required for optimal charge transport. This approach is universal for state-of-the-art materials in OPVs, light-emitting diodes (OLEDs), and field-effect transistors (OFETs).

“This methodology measures how similar molecules are to one another based on their molecular interactions,” Corzo explains. “You can select solvents that are alike at the molecular level but have beneficial properties, including reduced toxicity, or that originate from renewable sources.”

The method showed that plant-based solvents called terpenes – a group that includes the aromatic oils eucalyptol and limonene – could be suitable replacements. These solvents can be derived from plant residues, such as eucalyptus leaves or orange peel, or be produced from algae and microorganisms in bioreactors, researchers explain.

As potential carbon-negative solvents, solvent blends based on these substances proved to be an excellent fit for OPV manufacture. “We obtained solar cells with efficiencies above 16 percent using terpene-based inks – essentially the same as from chlorinated solvents – but with an 85 percent lower carbon footprint and with the potential to become carbon negative in the future,” Corzo says.

The team created an interactive library for green solvent selections and made it publicly available through the OMEGALab website. “We believe that multiple industries and tech developers will benefit from terpene solvent development,” Baran adds. “This library can go beyond the use of green solvents for organic electronics because terpenes are also used in food and fragrance industries, for instance.”

Journal reference:

- Daniel Corzo, Diego Rosas-Villalva, Amruth C, Guillermo Tostado-Blázquez, Emily Bezerra Alexandre, Luis Huerta Hernandez, Jianhua Han, Han Xu, Maxime Babics, Stefaan De Wolf, and Derya Baran. High-performing organic electronics using terpene green solvents from renewable feedstocks. Nature Energy, 2022; DOI: 10.1038/s41560-022-01167-7