Robotics, for a few years, is one of the technologies that has grown the most in the world. A large part of the innovations that are carried out every day has a certain relationship with artificial intelligence. In fact, there are more and more practical applications, even in the construction sector.

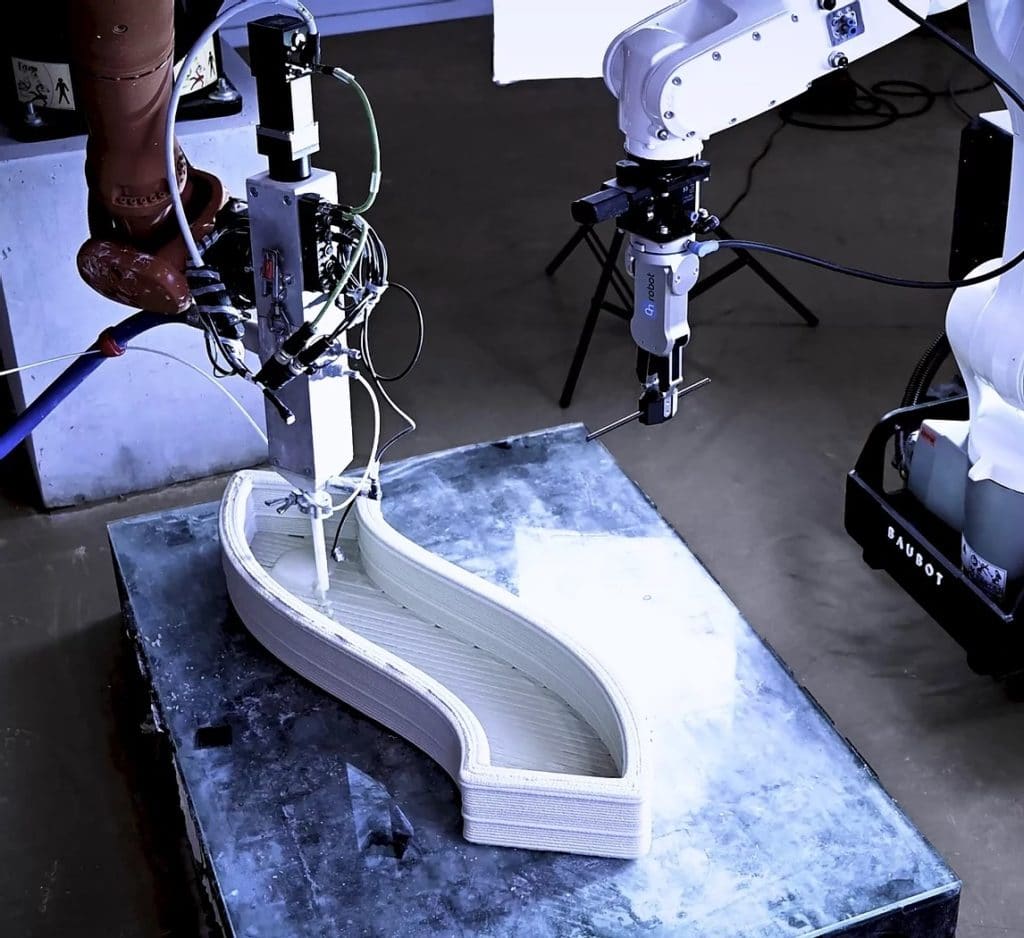

Printstones, an Austrian startup focusing on the development of digital manufacturing processes and mobile robotics solutions for the construction industry, has presented its latest prototype, a mobile multi-tasking construction bot called the Baubot. The construction bot can carry heavy loads, lay bricks, and even sand sheetrock, feats once only performed by folks in hardhats and steel-toed boots.

The Baubot has a modular design, meaning it allows for third-party customer modifications with ease. The electric-drive robot moves around the construction site at a maximum speed of 3.2 km/h, and thanks to its compact dimensions and tank-like all-terrain tracks, it can climb stairs, navigate through doorways.

The onboard batteries are charged for approximately eight hours of operation. In the front part, there is an arm – a multi-axis KUKA manipulator equipped with various tools to help with construction tasks such as milling and drilling, driving in screws, plasma cutting, welding, laying bricks, sanding and painting surfaces, and more.

It can be controlled manually using a smartphone interface or set to follow pre-programmed commands. In the future, Printstones intends to add BIM data functionality, which can be used to simulate the work environment and optimize work processes.

The system is available in several versions. The version of the Baubot MRS10-100, designed for work in confined spaces, has a lifting capacity of 10 kg for the manipulator and 500 kg for the platform. The reach of the robot arm is 1000 mm. The more powerful version of the Baubot MRS70-210 is capable of handling objects weighing up to 70 kg, and the chassis can withstand a load of up to 900 kg. The reach of the robot arm is 2100 mm. In addition, the company is working on the SRS100-400 transportable platform, an additive-subtractive gantry system with a payload of 100 kg and a production area of 4.2 square meters.

The robot that Printstones has developed is specially designed to meet the needs in the construction field for the coming years. In fact, work is already underway on how to achieve communication between different units so that they work in a coordinated way.

Baubot construction bots are already being offered for sale, complete with a software development toolkit, so users can program machines to suit their needs. The price highly depends on the application and amount of engineering, starting from €150K per unit, and you will have to wait about six months from order to delivery.