Despite the impressive performance of recent marine robots, many of their components are non-biodegradable or even toxic and may negatively impact sensitive ecosystems. Scientists seek to minimize this risk by creating new ways to build naturally decomposable robots.

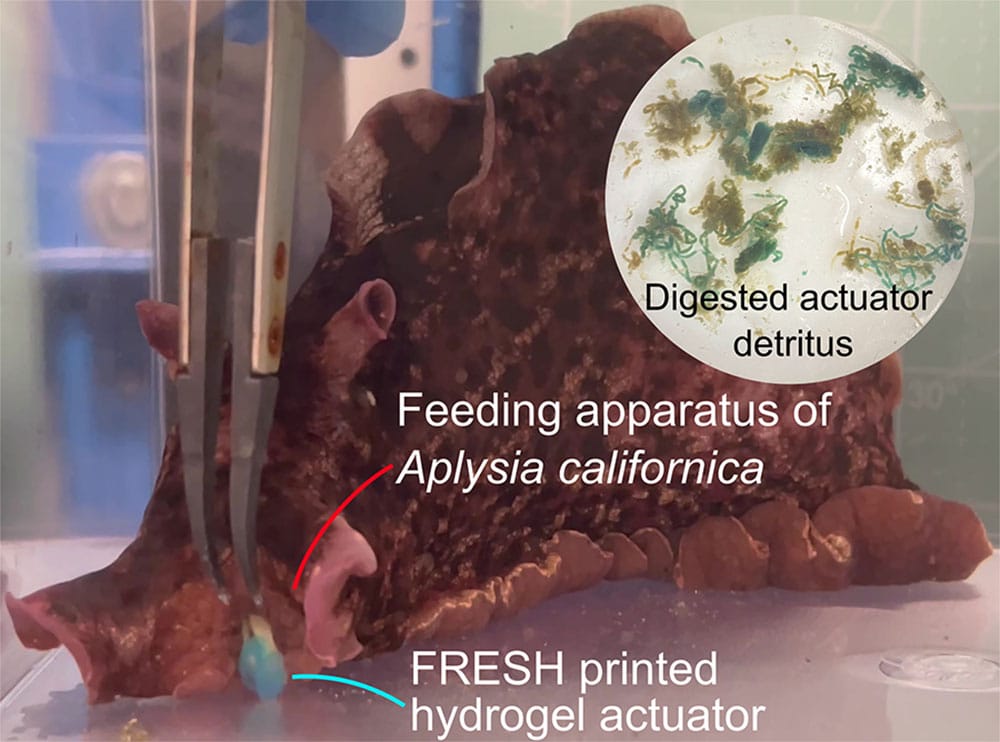

Researchers at Carnegie Mellon University are developing new ways to fabricate biodegradable actuators for marine applications. Using a bio-ink made of materials sourced from common brown seaweeds, the team identified designs and printing parameters that allow water-tight structures to be printed using the FRESH Printing method.

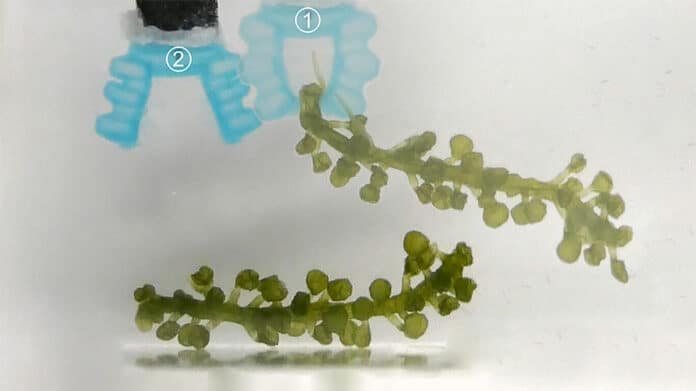

The new approach allows the fabrication of small-scale, very soft actuators that can extend, bend, and twist. They can also be combined into structures for gripping and positioning. The research team used seaweed-based inks that rely on calcium to crosslink and form gels. This allowed the team to leverage the material properties in order to create actuators that can change shape and stiffness by varying the degree of crosslinking in the actuators.

In addition to their robotic functionality, the actuators are fully biodegradable, degrading in natural ocean conditions within seven days. The actuators can also be safely consumed by marine organisms – which means if lost or damaged during use, the actuators pose minimal risk to the environment.

“How do we balance the need for advanced soft robotic structures with the potential environmental impact that results from their creation? We believe that the biodegradable actuators printed using FRESH are a promising solution, and we are excited to continue making improvements,” said Ravesh Sukhnandan, a Ph.D. student in mechanical engineering.

The research team hopes to further understand actuator performance in natural environments and extend this printing approach to complete robotic structures.

“We are thrilled to be able to continue this project where Wen left off,” said Avery Williamson. “It’s incredibly exciting to be developing new tools and methods for technologies with clear sustainable applications.”

Journal reference:

- Wenhuan Sun, Avery S. Williamson, Ravesh Sukhnandan, Carmel Majidi, Lining Yao, Adam W. Feinberg, Victoria A. Webster-Wood. Biodegradable, Sustainable Hydrogel Actuators with Shape and Stiffness Morphing Capabilities via Embedded 3D Printing. Advanced Functional Materials, 2023; DOI: 10.1002/adfm.202303659