The roles and responsibilities of firefighters have changed significantly over the past few decades. Firefighters must perform structure firefighting, search, rescue, mitigation of hazardous materials, and disaster response. Also, increased calls for firefighters to respond to potentially violent emergencies, such as active shooters these conditions demand better physical protection.

No other item is more classically associated with firefighters than their helmets. It not only provides a sense of security but also a sense of confidence when worn. Although designed to protect firefighters’ heads from thermal and low-velocity direct impact, helmets often contribute to additional exertion and sprain-related head and neck injuries because of their bulk and weight.

Firefighters need effective, affordable equipment they can rely on to support their increasingly demanding jobs.

The Department of Homeland Security’s (DHS) Science and Technology Directorate (S&T) and Texas Tech University (TTU) researchers are jointly developing a protective and lightweight NextGen firefighter helmet to protect firefighters that will provide firefighter both fire and ballistic protection and mitigate the risk of blunt head trauma.

It provides adequate functional mobility and postural stability, reducing the risk of injury to the cervical spine and neck muscle fatigue. It also supports accessories that expand the firefighter’s capabilities.

A modern firefighter helmet will be integrated with several safety features such as thermal protection, communication devices, face shields, visors, thermal imaging, breathing apparatus masks, and lighting. At the same time, make it lighter so that the helmet’s center of gravity does not change.

The new device will use alternative materials and advanced ergonomic design solutions to eliminate traditional helmet systems dangers. The NextGen firefighter helmet will have a shell that can absorb energy on impact and dissipate it rapidly without damaging the skull or brain.

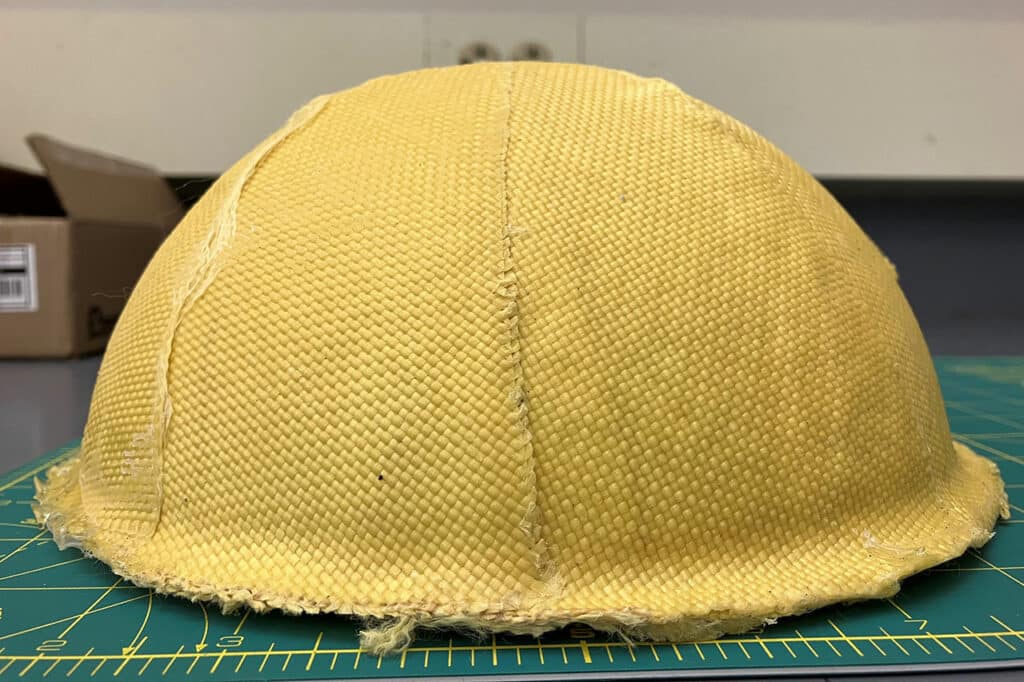

Researchers are exploring Kevlar fiber material for NextGen firefighter helmets because of its melting point of 1040°F (560°C), which has proven highly effective in ballistic helmets and body armor. Kevlar fiber can reinforce thermosetting resins, creating a shell that meets ballistic and thermal protection standards.

The helmet combines principles and practices from four key areas- reverse engineering, materials design, injury biomechanics, and human factors engineering.

The prototypes of the firefighter helmet will be tested with state-of-the-art equipment such as the Delsys Trigno wireless electromyography systems, 10-camera Eagle optical digital motion capture systems, and Pupil Core-eye trackers.

This equipment combines Abaqus finite-element modeling software to develop human head and neck models, HyperMesh to process helmet imaging data, and OpenSim musculoskeletal modeling software to develop head and neck biomechanical models to build a digital helmet prototype.

The NextGen firefighter helmet is expected to meet various protection standards and key performance parameters, such as the NFPA 1951:2013 protective standard for technical rescue incidents and the United States Occupational Safety and Health Administration 1910.156 fire brigade standard.

Weighing in at 62 oz (1.75 kg) for the large and 57 oz (1.62 kg) for the medium, this firefighter helmet is comfortable, adjustable, has a maximum range of motion, no snag points, and is easy to don and off.

Once the prototype is ready in mid-2023, an operational field evaluation will be conducted in coordination with S&T‘s National Urban Security Technology Laboratory. The main goal of the researchers is to commercialize this helmet.

After the commercialization of the NextGen firefighter helmet, it will not only increase the firefighter’s range of protection by providing injury-reducing helmets; It will promote new safety standards and improve the collective knowledge of material design.