A team of researchers from Northwestern University has developed a new fuel cell that can harvest energy from microbes living in dirt.

The completely soil-powered technology, which is roughly the size of a standard paperback book, could power underground sensors utilized in precision agriculture and green infrastructure.

It could also be an eco-friendly and sustainable alternative to batteries, which contain toxic and flammable chemicals that have negative impacts on the environment and contribute to electronic waste.

The researchers tested a new fuel cell by using it to power sensors that measured soil moisture and detected touch, a capability that could be valuable for tracking passing animals. Additionally, they equipped the soil-powered sensor with a tiny antenna to enable wireless communication and transmit data to a neighboring base station by reflecting existing radio frequency signals. The fuel cell worked in both wet and dry conditions, and its power also outlasted similar technologies by 120%.

“The number of devices in the Internet of Things (IoT) is constantly growing,” said Northwestern alumnus Bill Yen, who led the work. “If we imagine a future with trillions of these devices, we cannot build every one of them out of lithium, heavy metals, and toxins that are dangerous to the environment. We need to find alternatives that can provide low amounts of energy to power a decentralized network of devices. In a search for solutions, we looked to soil microbial fuel cells, which use special microbes to break down soil and use that low amount of energy to power sensors. As long as there is organic carbon in the soil for the microbes to break down, the fuel cell can potentially last forever.”

“These microbes are ubiquitous; they already live in soil everywhere,” said Northwestern’s George Wells, a senior author on the study. “We can use very simple engineered systems to capture their electricity. We’re not going to power entire cities with this energy. But we can capture minute amounts of energy to fuel practical, low-power applications.”

In recent years, farmers have been adopting precision agriculture to enhance their crop yields. This approach relies on measuring precise levels of moisture, nutrients, and contaminants in the soil to make informed decisions that can improve crop health. However, this requires a widespread, dispersed network of electronic devices that can continuously collect environmental data.

“If you want to put a sensor out in the wild, in a farm, or in a wetland, you are constrained to putting a battery in it or harvesting solar energy,” Yen said. “Solar panels don’t work well in dirty environments because they get covered with dirt, do not work when the sun isn’t out, and take up a lot of space. Batteries also are challenging because they run out of power. Farmers are not going to go around a 100-acre farm to regularly swap out batteries or dust off solar panels.”

To overcome this challenge, researchers such as Wells, Yen, and their collaborators have been exploring the possibility of harvesting energy from the existing environment. Yen explained that they could potentially harvest energy from the soil that farmers are already monitoring.

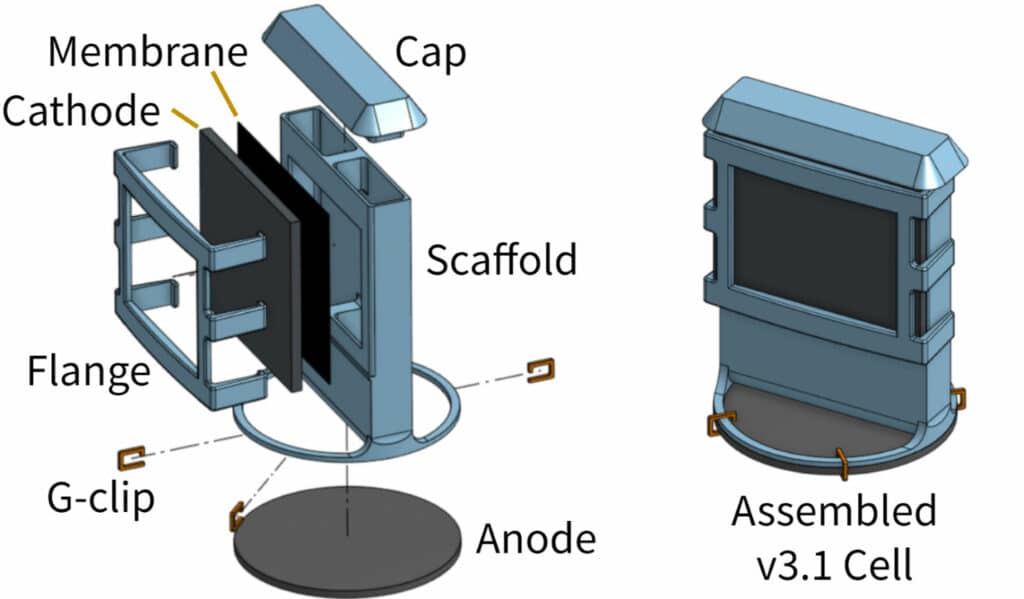

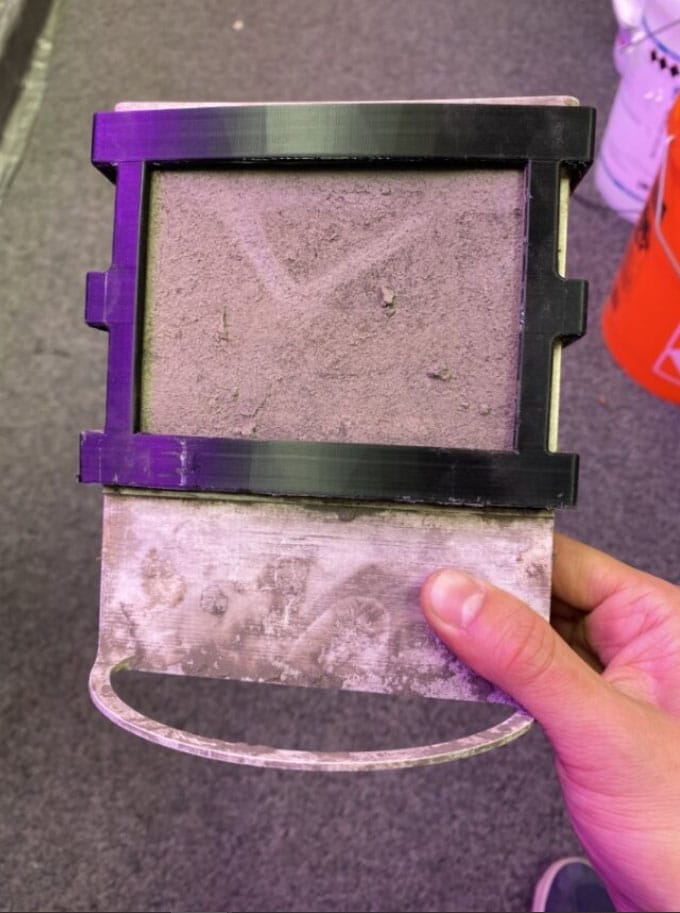

Yen and his team embarked on a two-year journey to develop a practical and reliable soil-based MFC. They created and compared four different versions, collected nine months of data on each design’s performance, and finally tested the best-performing prototype in an outdoor garden. The secret behind its success was its geometry, which differed from the traditional design. Instead of a parallel anode and cathode, the winning fuel cell used a perpendicular design, with the anode made of carbon felt and the cathode made of an inert, conductive metal. This design worked well in both dry and water-logged environments.

The device has a vertical design to ensure that the top end is flush with the ground’s surface. This device has a 3D-printed cap on top to prevent debris from falling inside and a hole on top to enable consistent airflow.

The lower end of the cathode remains deep beneath the surface to stay hydrated from the moist surrounding soil, and it is coated with waterproofing material to allow it to breathe during a flood. The device generates 68 times more power than needed to operate its sensors and can withstand large changes in soil moisture.

All components for their soil-based MFC can be purchased at a local hardware store, researchers say. Next, they plan to develop a soil-based MFC made from fully biodegradable materials. Both designs bypass complicated supply chains and avoid using conflict minerals.