In the world’s first, HYFLEXPOWER consortium successfully operated a gas turbine with 100% renewable hydrogen.

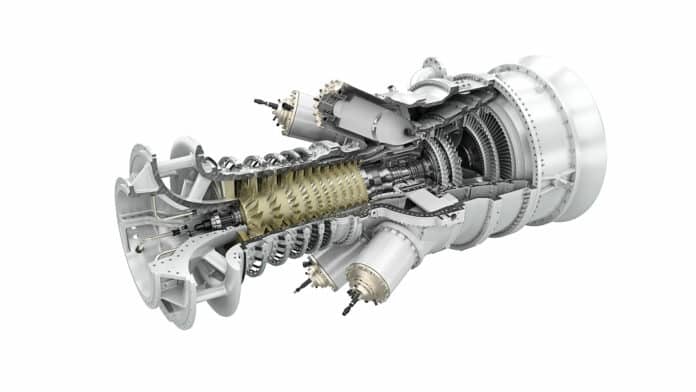

The demonstration took place at the HYFLEXPOWER project site at the Smurfit Kappa paper packaging plant in Saillat-sur-Vienne, France. For the demonstrator project, the hydrogen is produced by a 1MW electrolyzer on-site, stored in an almost one-ton tank, and used to power a Siemens Energy SGT-400 industrial gas turbine.

The latest successful series of tests on a Siemens Energy SGT-400 industrial gas turbine offers a decisive outlook for carbon-neutral power generation and the decarbonization of industry. The tests show the turbine can be fueled with up to 100% renewable hydrogen as well as with natural gas and any blends in between.

Funded by the European Commission under the Horizon 2020 Framework Program, the HYFLEXPOWER project aims to demonstrate that renewable hydrogen can serve as a flexible means of storing energy, which can then be used to power a high-power industrial turbine.

For this, an existing Siemens SGT-400 industrial gas turbine is upgraded to convert stored hydrogen into electricity and thermal energy with stored hydrogen and demonstrate an industrial-scale power-to-H2-to-power solution.

In 2022, an initial series of tests allowed for the industrial gas turbine to operate with a 30% hydrogen content when mixed with natural gas. Now, the power-to-hydrogen-to-power demonstrator has demonstrated that modern turbines equipped with dry emissions technology can be powered with up to 100% hydrogen, as well as with natural gas and any mixtures in between.

“The knowledge and experience gained from the HYFLEXPOWER project, where we installed the 1st gas turbine to run on 100 percent hydrogen, will help us to continue developing our entire gas turbine fleet for a hydrogen-based future. The interaction between electrolysis, storage, and hydrogen conversion at one site has been impressively demonstrated, and now it’s a matter of scaling the results,” says Karim Amin, Member of the Executive Board of Siemens Energy.

The HYFLEXPOWER consortium comprises Siemens Energy, ENGIE via its subsidiary ENGIE Solutions, Centrax, Arttic, the German Aerospace Center (DLR), and four European universities. As the lead of the consortium, Siemens Energy provided the electrolyzer for hydrogen production and developed the hydrogen gas turbine. ENGIE constructed the hydrogen production, storage, and supply for the demonstrator, while Centrax was responsible for the package upgrade to ensure safe operation with hydrogen fuel.

The German Aerospace Center (DLR), the Universities of Lund (Sweden), Duisburg-Essen (Germany), and University College London (UK) contributed to the development of hydrogen turbine technology. Arttic supported the operational project management, while NTUA in Athens (Greece) carried out an economic, environmental, and social analysis of the concept.

The project is now looking to extend its operation to industrial heat production and additional operational modes. It is also planned to explore ways of scaling up and commercializing decarbonized electricity generation.