The Geneva Motor Show 2020 is history thanks to the coronavirus. Even so, nothing has prevented major brands from presenting some of the innovations they had prepared, thanks to the online alternatives to conventional press conferences.

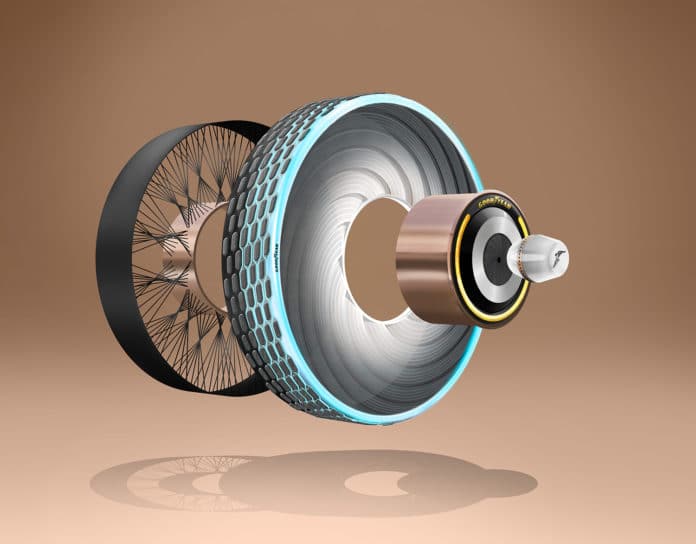

One of them is Goodyear, which has introduced its latest revolutionary self-regenerating concept tire called the ReCharge that can adapt and change to meet individual mobility needs. These tires never need to be replaced; they are renewed automatically. They will not need to be inflated and cannot be punctured, which makes maintenance easier.

The reCharge concept includes a number of innovative features that are built around three pillars: personalization, sustainability, and simplicity.

The new technology renews the wheels from the inside through a mixture of renewable materials. A more environmentally responsible alternative that reduces wear and contaminating particles that are released during abrasion and extends the life of the tire.

The idea is that instead of changing the wheels of our car when worn, the tire tread automatically regenerates. Capsules – filled with a biodegradable liquid compound – are inserted into the tire core. This liquid is responsible for regenerating the tread from the inside. It will allow it to build up a pattern on the outside of the tire as it wears to provide the necessary adhesion properties and an optimal contact spot.

Thanks to artificial intelligence, a driver profile would be created around which the liquid compound would be customized, generating a compound blend tailored to each individual.

The compound would be made from renewable materials that come from nature, including dandelion rubber and synthetic spider silk. Hence the brand speaks of sustainability, explaining that this material would make the tire “extremely durable and 100% biodegradable.” The company has also indicated that the recharge tire adapts to any surface or weather conditions.

The tread would be supported by a light-weight, non-pneumatic frame and tall-and-narrow shape. This is a thin, robust, low-maintenance construction that would eliminate the need for pressure maintenance or downtime related to punctures.

At the moment it is a futuristic concept, the company has not indicated when they could start to be manufactured, but there is no doubt that it would be a step for the sustainable mobility of tomorrow.