General Motors and Las Vegas-based MP Materials announced the formation of a strategic collaboration to develop a fully integrated U.S. supply chain for rare earth magnets. Under the long-term agreement, MP Materials will supply the automaker with US-sourced and manufactured rare earth materials, alloy, and finished magnets for the electric motors that will be used to power GM’s upcoming lineup of electric vehicles.

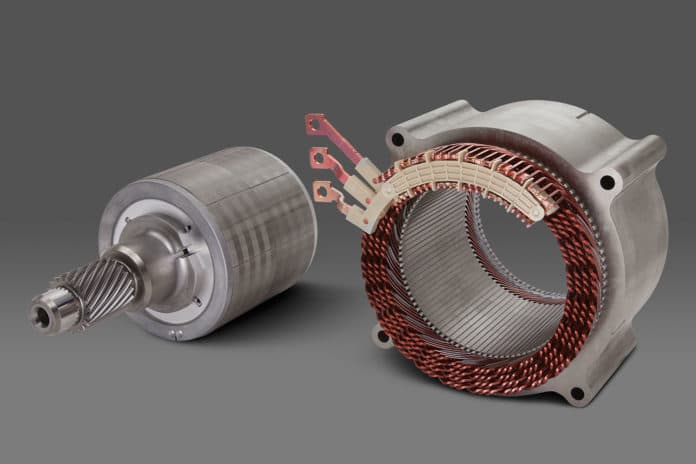

Electric motors are powered by permanent magnets, some of which are roughly the size of a pack of playing cards, but they’re generally made of rare earth metals. The magnets enable electric motors to transform electricity into motion, thus powering the vehicle. But these rare earth magnets, mostly made of neodymium (NdFeB), are almost exclusively mined and processed in China. With growing tensions between China and the United States, automakers are under increasing pressure to find more local, non-disputed sources of key resources.

This strategic collaboration seeks to accelerate the restoration of the U.S. rare earth supply chain at a commercial scale with high resiliency and environmental sustainability. MP Materials owns and operates the Mountain Pass rare earth mine and processing facility in California, the only active and scaled rare earth production site in America. Rare earth materials sourced from Mountain Pass will be transformed into metal, NdFeB alloy, and magnets at a new production facility that MP Materials will build in Fort Worth, Texas.

“We are building a resilient and sustainable EV manufacturing value chain in North America, from raw materials to cell manufacturing to electric drive motors and beyond, further accelerating GM’s vision to support a mass market for EVs,” said Shilpan Amin, GM vice president, Global Purchasing and Supply Chain. “Our work with MP Materials is another bold step forward that will help ensure that we meet our goal to lead the EV industry in North America in more than just sales.”

The new agreement with MP Materials will help ensure that most of the materials that comprise its Ultium EV platform will come from within North America by 2025. MP’s domestic supply chain spanning California and Texas will provide certainty of provenance, supply, and sustainability. Mountain Pass is a closed-loop, zero-discharge rare earth production facility with a dry tailings process that recycles more than 1 billion liters of water per year.

Waste generated during MP’s rare earth alloy and magnet manufacturing will be recycled back into the process. GM and MP Materials will also explore the potential to further optimize production efficiency and conserve natural resources through novel recycling approaches based on end-of-life, closed-loop principles.

GM is racing to boost its EV offerings, vowing to spend $35 billion on the development and production of 30 new electric vehicles by 2025.