Water-based flow batteries are attractive for storing renewable energy in urban areas, as they do not use rare earth and toxic materials. However, they also have some drawbacks – such as very low energy density and low charge and discharge rates – that limit their widespread application.

To address this issue, David Robber, a researcher from Switzerland’s Federal Laboratories for Materials Science and Technology (EMPA), is trying to develop a hybrid flow battery and lithium-ion battery.

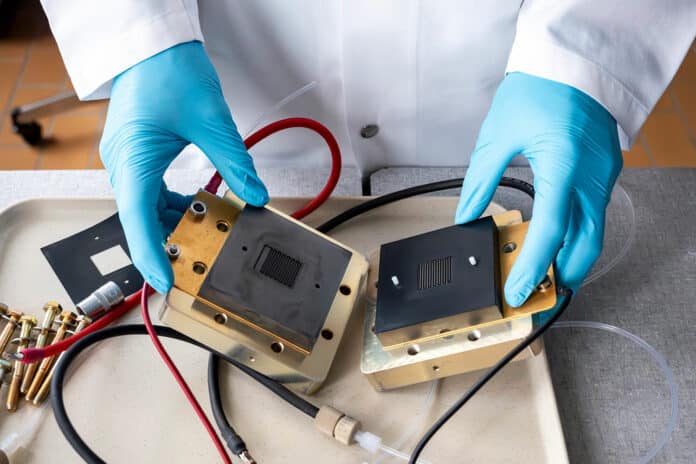

Unlike conventional lithium-ion batteries, redox flow batteries store energy not in solid electrodes but in tanks containing liquid electrolyte solutions. The charging and discharging process takes place through an electrochemical cell, with the electrolytes being pumped through it.

While liquid batteries are not practical for use in cell phones, laptops, or cars, they are highly promising for stationary storage solutions. Since the energy is stored outside the actual cell, flow batteries can be easily and precisely scaled. A larger electrochemical cell makes the battery charge and discharge faster, whereas larger electrolyte tanks allow for the storage of more energy.

Another point for flow batteries: If water-based electrolytes are used, they are basically non-flammable, unlike conventional lithium-ion batteries. Nevertheless, the technology has not yet caught on.

“Flow batteries have an energy density around ten times lower than batteries made of solid storage materials,” he explains. The more storage material can be dissolved in the electrolyte, the higher the energy density of a flow battery. “However, high concentrations thicken the solution, and you need a lot more energy to pump it through the cell,” David Robber says.

The researcher wants to develop a hybrid of a flow battery and a lithium-ion battery by adding solid storage materials to the flow battery’s tank.

“If the dissolved material and the solid storage material are precisely matched, they can transfer energy between each other,” Reber elaborates. “This allows the scalability of flow batteries to be combined with the high energy density of batteries with solid storage materials.”

For this, the researcher first needs to find suitable pairs of materials that enable the energy exchange while also remaining stable over an extended period of time. Ideally, a redox flow battery should be able to operate for about 20 years.

One of Reber’s ideas is to use a chelate as the dissolved storage material: a multi-armed organic molecule that “wraps” around a metal ion. Depending on how many arms the organic molecule – the ligand – has, the redox potential changes.

Reber already conducted research on chelate-based redox flow batteries during his postdoctoral period at the University of Colorado Boulder. At the end of his Ambizione funding period of four years, Reber hopes to have a well-functioning battery with additional solid storage.

“If this approach works, the potential applications are very diverse,” he says. For example, compact flow batteries with a flexible form factor would be much easier to integrate in urban areas. “All it would take would be pumps and a few pipes,” the researcher adds.