Flow batteries are a promising technology for large-scale energy storage. However, the footprint and capital cost need further reduction for flow batteries to be commercially viable.

Now, researchers at the Georgia Institute of Technology have developed a more compact flow battery cell configuration that reduces the size of the cell by 75% and correspondingly reduces the size and cost of the entire flow battery. This could revolutionize how everything from major commercial buildings to residential homes are powered.

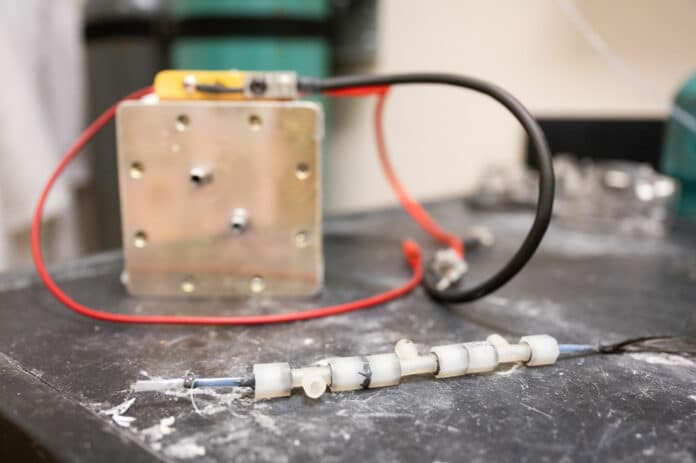

To reduce footprint and cost, the researchers turned to a submillimeter bundled microtubular (SBMT) flow battery cell configuration that significantly improves volumetric power density by reducing the membrane-to-membrane distance by almost 100 times and eliminating the bulky flow distributors completely. This SBMT flow battery cell configuration is commonly used in chemical separation made of a fiber-shaped filter membrane known as a hollow fiber.

The microtubular membrane in the design works as an electrolyte distributor at the same time without the need for large supporting materials. The bundled microtubes create a shorter distance between electrodes and membranes, increasing the volumetric power density.

To validate their new battery configuration, the researchers used four different chemistries: vanadium, zinc-bromide, quinone-bromide, and zinc-iodide. All chemistries are functional, but two of them were the most promising.

Vanadium was the most mature chemistry but also less accessible, and its reduced form is unstable in the air. The team found zinc iodide was the most energy-dense option, making it the most effective for residential units. Additionally, zinc-iodide has less of a supply chain issue compared to lithium and also can be turned into zinc oxide and dissolved in acid, making it much easier to recycle.

Researchers say this electrochemical solution for this unique shape of the flow battery proved more powerful than conventional planar cells. Using zinc-iodide chemistry as a demonstration, the new SBMT cell could run for more than 220 hours, corresponding to >2,500 cycles at off-peak conditions. It could also potentially reduce the cost from $800 to less than $200 per kilowatt hour by using the recycled electrolyte.

“The superior performance of the SMBT was also demonstrated by finite element analysis,” said Xing Xie, an assistant professor in the School of Civil and Environmental Engineering. “This simulation method will also be applied in our future study for cell performance optimization and scaling up.”

Researchers are now working on optimizing cell performance and commercialization, focusing on developing batteries with different chemistries like vanadium and scaling up their size. Scaling will require coming up with an automated process to manufacture a hollow fiber module, which is now done manually, fiber by fiber.

The SBMT flow batteries could also be applied to different energy storage systems like electrolysis and fuel cells. The technology could even be strengthened with advanced materials and different chemistry in various applications.

Journal reference:

- Yutong Wu, Fengyi Zhang, Ting Wang, Po-Wei Huang, Alexandros Filippas, Haochen Yang, Yanghang Huang, Chao Wang, Huitian Liu, Xing Xie, Ryan P. Lively, and Nian Liu. A submillimeter bundled microtubular flow battery cell with ultrahigh volumetric power density. Proceedings of the National Academy of Sciences, 2023; DOI: 10.1073/pnas.2213528120