In the world of wind power, damp and cold weather can be a wind turbine‘s worst enemy. Rotor blades covered in ice can cause rotational imbalance, leading to increased wear and tear. In such cases, turbines must be shut down for several days, resulting in significant losses for operators due to the pause in electricity production.

Traditional de-icing methods, such as heating mats or spraying de-icing agents from helicopters, can be incredibly expensive.

Now, for the first time, a team of experts from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM and the Fraunhofer Institute for Manufacturing Engineering and Automation IPA has succeeded in using drones to protect rotor blades against ice. This new cost-effective alternative technique was developed as part of the “TURBO – Temporary coating by means of drones” project.

In order to use drones to prevent ice, a number of conditions have to be met. The coating materials used for this purpose not only have to be environmentally friendly, but they also need to demonstrate good adhesion and sufficient durability so that they remain on the rotors for weeks and protect them from ice. The spraying system used for applying these coatings needs to be highly accurate yet lightweight at the same time. Finally, the drones themselves need to have a high payload and allow for very precise control.

To fulfill all of these requirements, researchers developed a prototype coating material made from urea and wax. This coating material is environmentally friendly, demonstrates good adhesion, and can be efficiently applied using a spray technique, ensuring quick drying.

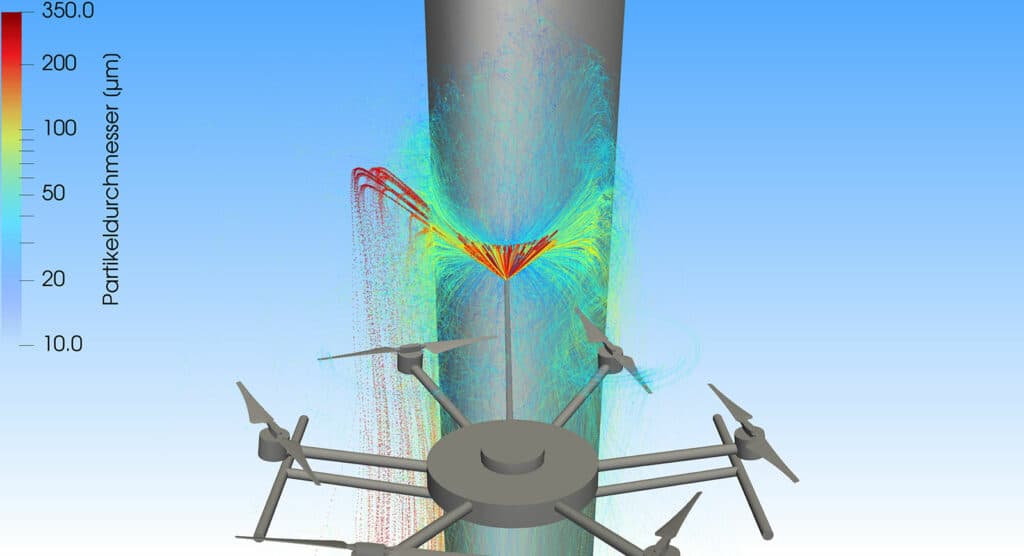

To protect against frost formation, the coating underwent testing in an ice chamber at the institute, confirming its reliable performance. Fraunhofer IPA’s team built the equipment to apply the coating, which consists of a small pump pressing the fluid urea/wax mixture at high pressure into a long, thin lance with a nozzle of just 0.3 millimeters diameter.

Even at wind speeds of up to 35 km/h, the airless pump system can spray droplets with a diameter of 100 micrometers precisely onto the rotor blades’ edges, where they solidify. The edges are particularly important as this is where the icing process starts when wet, cold air hits the turbine.

Dr. Oliver Tiedje, project manager at Fraunhofer IPA, and his team determined the technical parameters using fluid dynamic simulations.

“Our decades of experience in modeling coating processes really helped us out. We were able to draw on this expertise,” says the physicist. “However, we did have to adapt the process parameters to the complex geometry of the wind turbines.”

The researchers are planning to collaborate with industry partners to refine the technique and make it suitable for large-scale production. Drones can be employed to apply coatings in a variety of applications, such as protecting wind turbines and overhead lines in rail transport from ice, as well as refurbishing buildings by repairing defects in the render on hard-to-reach sections.