Japanese space infrastructure company Interstellar Technologies (IST) has reached a new milestone with the completion of a static fire test for its small satellite launch vehicle, ZERO, powered by Liquid Biomethane (LBM).

The test was held at Hokkaido Spaceport’s (HOSPO) ‘Launch Complex-0 (LC-0)’ in Taiki, Hokkaido, and showcased the potential of biomethane – derived from cow dung gathered from local dairy farms – as a sustainable rocket fuel. During the experiment, the engine generated a horizontal blue-and-orange flame that lasted for approximately 10 seconds.

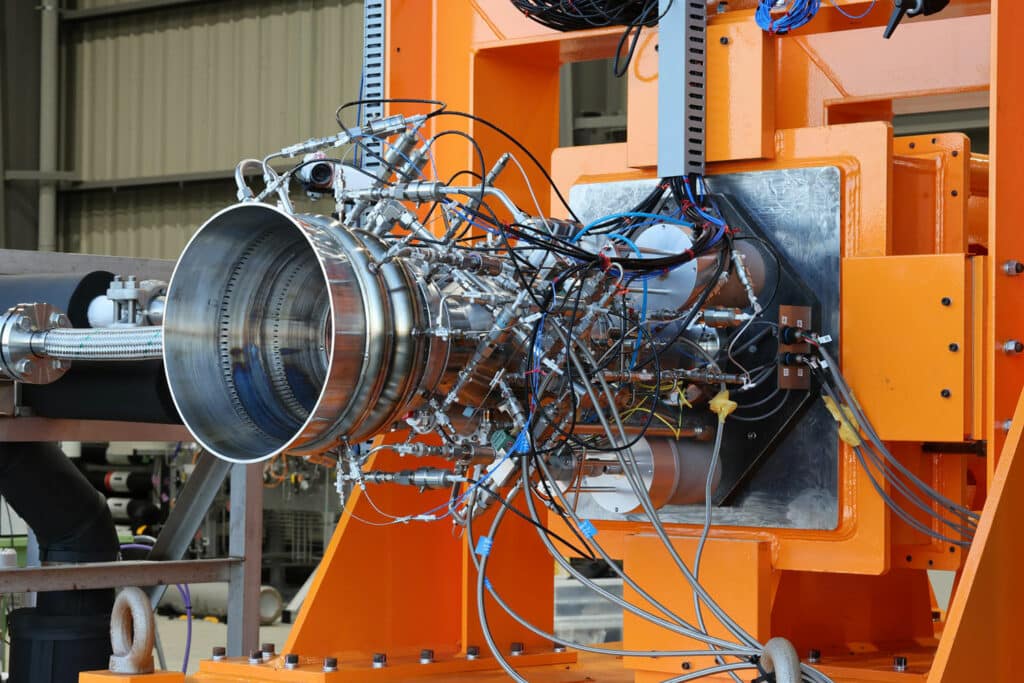

To achieve excellent combustion performance, the combustion chamber of ZERO has undergone extensive research and development efforts in collaboration with Tokyo University and JAXA. This has led to design improvements, which have lowered the manufacturing costs of the rocket engine, which are estimated to constitute half of the overall expenses.

The successful test will help IST to advance the development and manufacturing of a 130kN-class operational model based on the knowledge gained from the design, manufacturing, and testing process of a 60kN-class subscale model.

ZERO is a small satellite launch vehicle that is designed to cater to the increasing demand for small-sized satellites in recent years. With an eye on recent trends and local and global demand, ZERO is enhancing its capacity to launch satellites of up to 800 kilograms into Low Earth Orbit (LEO). ZERO is 32 meters long with a 2.3-meter diameter and has a total weight of 71 tons.

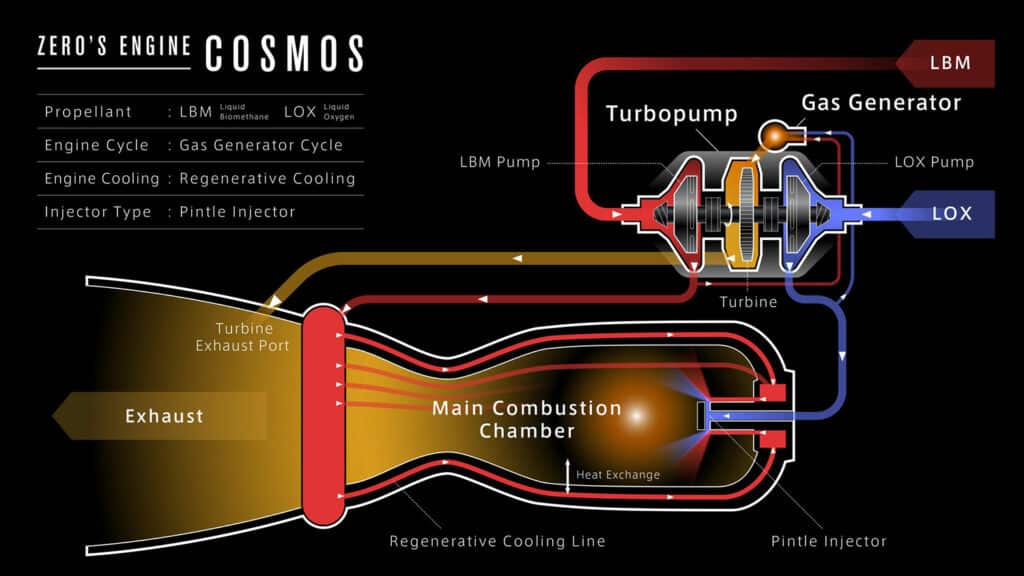

It operates as a liquid-propellant rocket, using LBM as its fuel and liquid oxygen as the oxidizer. This is the first time IST has adopted the gas generator cycle, which involves burning some of the propellants in a gas generator to drive a turbopump at tens of thousands of rotations per minute and deliver the fuel to the combustion chamber at high pressure.

Featuring a two-stage design, the rocket incorporates a pintle injector, which reduces the number of components and improves combustion efficiency. The pintle injector delivers propellants (liquid fuel and oxidizer) into a rocket engine’s combustion chamber in a controlled manner.

The regenerative cooling system also efficiently utilizes the fuel for cooling purposes within the combustion chamber walls. Tests for the combustion chamber, turbopump, and gas generator have been conducted, with future plans to integrate them.

The successful tests are an important step toward the actual liftoff of this small satellite launch vehicle rocket by 2025.

Liquid methane has emerged as a superior fuel choice for rocket launches due to its various advantages, such as fuel performance, price, availability, ease of handling, and environmental impact. Air Water Group has been making efforts to establish a circular supply chain for liquid biogas methane (LBM), which is produced by refining methane from biogas obtained from livestock manure in the Hokkaido Tokachi area.

The LBM used in the recent test is produced by separating and refining methane, the primary component of biogas, and then liquefying it at approximately -160°C. It’s impressive that it achieves such high purity levels, which are comparable to those of conventional rocket fuels used in the past. Impressed by its performance and procurement excellence, IST has decided to use Air Water’s LBM as fuel for its upcoming ‘ZERO’ rocket.

Methane emissions from cattle pose a serious challenge in global warming as it is a potent greenhouse gas, second only to carbon dioxide. Additionally, livestock manure also causes issues like odor and water pollution, which are becoming increasing societal concerns. Through the use of LBM, IST, and Air Water, Hokkaido is working towards making the majority of rocket fuel sustainable, which is a concrete contribution towards mitigating climate change.