The collective behaviors of ants, honeybees, and birds to solve problems and overcome obstacles are something researchers have developed in aerial and underwater robotics. Such behavior has now been copied in a small 3D-printed multi-legged robot that may someday find use in applications such as searching for survivors at disaster sites.

Yasemin Ozkan-Aydin, assistant professor of electrical engineering at the University of Notre Dame, has built these small multi-legged robots capable of maneuvering in challenging environments and accomplishing tasks collectively, mimicking their natural-world counterparts. The four-legged robots measure 15 to 20 centimeters, or roughly 6 to 8 inches, in length, and are equipped with a lithium polymer battery, microcontroller, and three sensors – a light sensor at the front and two magnetic touch sensors at the front and back.

Its four flexible legs reduced the need for additional sensors and parts and gave the robots a level of machine intelligence, which helped when interacting with rough or uneven terrain. “You don’t need additional sensors to detect obstacles because the flexibility in the legs helps the robot to move right past them,” said Ozkan-Aydin. “They can test for gaps in a path, building a bridge with their bodies; move objects individually; or connect to move objects collectively in different types of environments, not dissimilar to ants.”

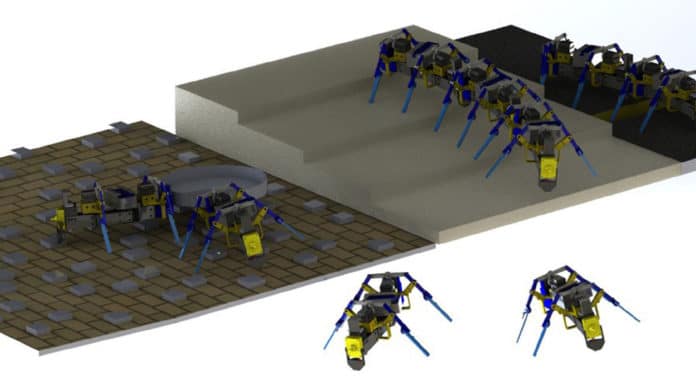

The robots use their magnetic touch sensors to establish their orientation relative to one another and to link their bodies together in a chain. This way, they can accomplish tasks, such as gap traversal, stair climbing, and object transport over uneven terrains, and can even work together to carry objects too large or heavy for an individual bot to manage.

Ozkan-Aydin started building these robots in early 2020 and continued to improve and test them at home or in her yard. The four-legged robots are tested over grass, mulch, leaves, and acorns. They are also tested over shag carpeting, and rectangular wooden blocks were glued to particle board to serve as rough terrain.

She expects the study’s findings will inform the design of low-cost legged swarms that can adapt to unforeseen situations and perform real-world cooperative tasks such as search-and-rescue operations, collective object transport, space exploration, and environmental monitoring. Ozkan-Aydin is now working on improving the system’s control, sensing, and power capabilities, which are essential for real-world locomotion and problem-solving. She plans to use this system to explore the collective dynamics of insects such as ants and termites.

“For functional swarm systems, the battery technology needs to be improved,” she said. “We need small batteries that can provide more power, ideally lasting more than 10 hours. Otherwise, using this type of system in the real world isn’t sustainable.” Additional limitations include the need for more sensors and more powerful motors – while keeping the size of the robots small.