When spacecraft return to Earth from space, they face a significant problem. The heat develops as the spacecraft re-enters Earth’s atmosphere. The friction between the vehicle and the air creates a temperature where most metals and alloys melt or fail. Today’s heat shields rely on an ablation mechanism to remove unwanted heat by having pieces of the shield gradually burn off.

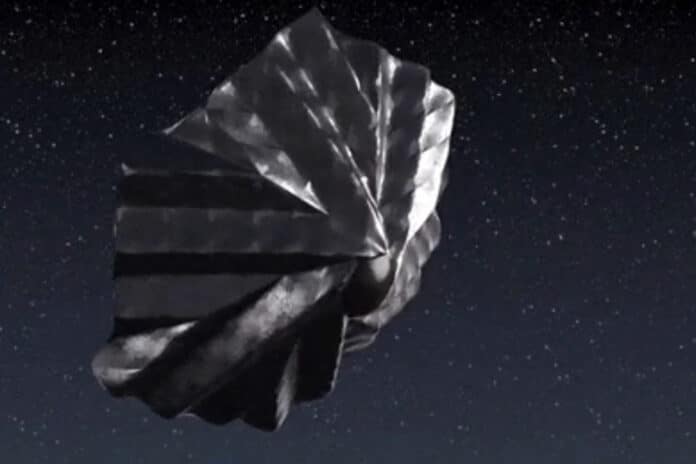

The European Space Agency (ESA) and UK-based Space Forge have jointly developed an origami-like heat shield design named Pridwen, after King Arthur’s legendary shield. Pridwen relies on radiation, and its high-temperature alloy fabric has a large enough surface area that the heat flux can spread evenly over it and dissipate slowly.

According to Space Forge, the Pridwen shield has been designed to pack as much surface area as possible into a small package. The origami-like unfolding means that Pridwen is not bound to the rocket’s diameter that initially lifted the payload into space. Therefore, it can be much larger than a conventional invariant shield. The company believes this design will dissipate heat to keep the spacecraft cool over time. Since the shield is still in one piece, resetting it for use again is also possible.

In addition to protecting the spacecraft‘s re-entry from heat, the shuttlecock-style Pridwen is designed to slow it down. Space Forge believes a small satellite could be so slow that it would not need a parachute. The company has tested the shield in high-altitude drops at terminal velocity, with the net successfully catching the target.

The company developed Pridwen as part of a larger vision of in-orbit manufacturing high-value items such as pharmaceuticals, superconductors, and superalloys, which would be regularly returned to Earth.

The heat shield has undergone several drop tests from an altitude of 17 km and practiced pure capture of test objects falling at terminal velocity. The first Pridwen heat shield will fly aboard the company’s inaugural ForgeStar-1A mission later this year.

The project has been supported by ESA’s General Support Technology Programme and the UK Space Agency.