Aerospace service operators use highly advanced inspection instruments like borescope bespoke robotic devices to look inside the jet engine that provide precious inspection data. However, these instruments are limited in overall turbine coverage because factors such as gravity can cause the tip to stabilize naturally when not held up against the structure of the engine.

To overcome this problem, the American jet and turboprop engine company GE Aerospace introduced the Soft ElectroNics Skin-Innervated Robotic Worm (Sensiworm). It is a highly intelligent, highly sensitive soft robot that can act as an extra set of eyes and ears for Aerospace service operators to get information from inside the engine.

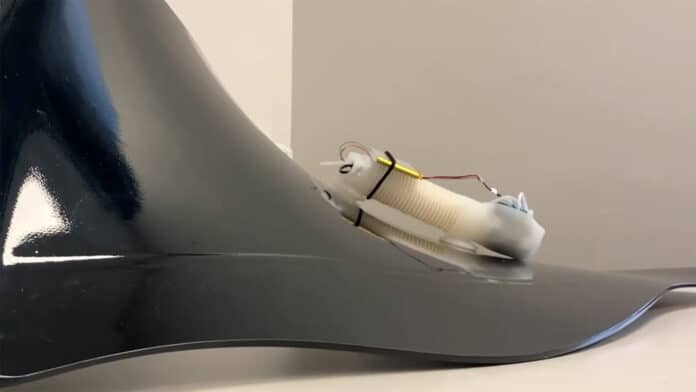

GE Aerospace’s Sensiworm is a highly flexible soft robot that resembles an inchworm. It is self-contained, with on-board power, computing, and pressure resources. Sensiworm enables less invasive inspection and repair of jet engines on the wing to reduce downtime.

Sensiworm could help further expand coverage and inspection capabilities inside an engine. It can be deployed through the turbine inlet or exhaust of an engine and provide coverage of a much larger swath of the turbine.

In lab-scale demonstrations, the team has demonstrated its ability to move easily on and around the various crevasses and curves of jet engine parts to detect cracks and corrosion.

Sensiworm has also been shown to accurately test and measure the thickness of thermal barrier coatings on engine parts to determine if the parts are maintaining the proper thickness.

Deploying self-propelling, compatible robots like Sensiworm will give operators virtually seamless access to inspect engines in the future without disassembling them.

The aim behind making Sensiworm is to provide on-wing service personnel with multiple trusted eyes and ears inside the engine with the ability to inspect and repair critical engine parts.

“With mini-robot companions like Sensiworm, service operators would have multiple additional sets of eyes and ears to perform on-wing inspections,” said Deepak Trivedi, Principal Robotics Engineer at GE Aerospace Research. “With their soft, compliant design, they could inspect every inch of a jet engine, transmitting live video and real-time data about the condition of parts that operators typically check. Sensiworm can even measure the thickness of thermal barrier coatings on parts that are applied to protect the parts from heat.”

“Currently, our demonstrations have primarily been focused on the inspection of engines,” Trivedi added. “But we’re developing new capabilities that would allow these robots to execute repair once they find a defect as well.”

Gity Samadi, PhD, Director of R&D Programs, SEMI Global Headquarters, said, “This project demonstrates our commitment to progress in Flexible Hybrid Electronics and beyond. It embodies the principles that drive our R&D funding consortium, mitigating risks for breakthrough technology that propels industry advancement.”

GE Aerospace developed the Sensiworm robot with funding and support from SEMI Flex Tech. The US Army Research Lab funds the program. The GE team also is partnered with Binghamton University and UES, Inc.