Printed circuit boards (PCBs) used in most electronic devices are typically made from organic materials such as resins, brominated flame retardants, chemical residues, and heavy metal components. Primarily this e-waste is dumped into landfills after use. Hence, these metals are difficult to recover and pollute soil and water systems, harming human health and the environment. Many researchers are working on biodegradable printed circuits to overcome this problem.

Now Germany-based Infineon Technologies has introduced Soluboard, a recyclable and biodegradable PCB substrate based on natural fibers and halogen-free polymers to help reduce e-waste.

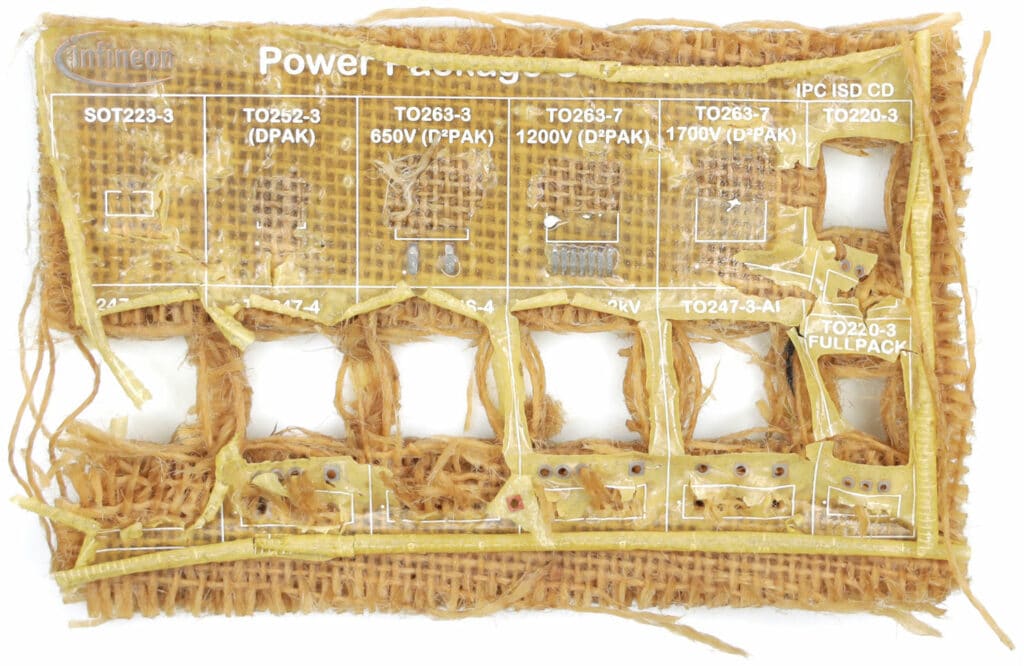

Soluboard is developed by UK-based startup Jiva Materials, which aims to help reduce the carbon footprint of the electronics industry. It is made from natural fibers and other biodegradable components that separate layers of composite material once immersed in hot water. This allows the natural fibers to compost. The remaining solutions and electronic components will be removed for reprocessing for disposal using standard household sewage systems.

“Adopting a water-based recycling process could lead to higher yields in the recovery of valuable metals,” said Jonathan Swanston, CEO and co-founder of Jiva Materials. “In addition, replacing FR-4 PCB materials with Soluboard would result in a 60 percent reduction in carbon emissions – more specifically, 10.5 kg of carbon and 620 g of plastic can be saved per square meter of PCB”.

By dissolving a circuit board made from Soluboard, 90% of its components can be reclaimed and remanufactured or recycled. The carbon footprint of one square meter of Soluboard PCB is estimated to be 7.1kg, and the carbon footprint of one square meter of standard FR-4 PCB is estimated to be 17.7kg. This equates to a total carbon footprint reduction of 60%. There is also a significant plastic saving of 620g per square meter of Soluboard compared to FR-4.

If Soluboard is widely adopted, recycled metals could see a 95% smaller carbon footprint than newly processed raw materials, which have a much lower carbon footprint than conventional glass-based fibers used in FR-4.

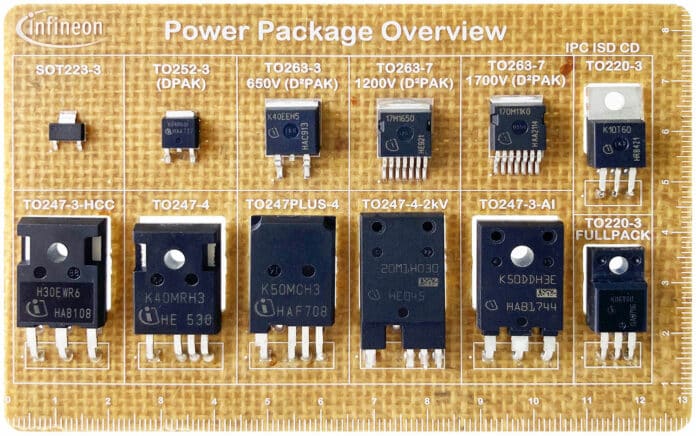

Using Soluboard technology, Infineon has produced three different demo boards and plans to expand its offering over the next few years.

“For the first time, a recyclable, biodegradable PCB material is being used in the design of electronics for consumer and industrial applications – a milestone towards a greener future,” said Andreas Kopp, Head of Product Management Discrete at Infineon’s Green Industrial Power Division. “We are also actively researching the reusability of discrete power devices at the end of their service life, which would be an additional significant step towards promoting a circular economy in the electronics industry.”

More than 500 units are already used to showcase the company’s power discrete portfolio, including a board featuring components for refrigerator applications. Based on the results of ongoing stress tests, the company plans to guide the reuse and recycling of power semiconductors removed from Soluboard, which can significantly increase the life of electronic components.

The tests will also give Infineon an understanding of the design and reliability challenges customers will face with new materials in their applications.

E-waste researchers have also developed a flash-heating method to recover precious metals. But for that, people need to stop dumping e-waste in landfills so that it can be recycled. To highlight this point and raise awareness, Envision Racing recently unveiled the Recover-E racing car made entirely from e-waste. Increasing awareness among researchers and companies to reuse and recycle electronic components will help reduce global carbon emissions.