Lithium-metal batteries (LMBs) are a promising alternative to lithium-ion batteries (LIBs), more commonly used today, given the much higher energy density associated with the lithium-metal anode.

Now, a team of materials scientists and chemists has taken a step forward towards this future. The team has determined the proper stack pressure that lithium metal batteries need to be subjected to during battery operation in order to produce optimal performance.

The LMBs seek to use pure lithium metal as the anode material, which delivers almost ten times the storage capacity of graphite anodes, thus enabling much higher cell energies. Despite this advantage over lithium-ion batteries, LMBs are not considered a viable option to power electric vehicles or electronics because of their short lifespan and potential safety hazards, specifically short circuits caused by lithium dendrite growth.

Previous researches found that subjecting LMBs to pressure during battery cycling increases performance and stability, helping to solve these lifespan challenges. But the reasons behind this were not fully understood.

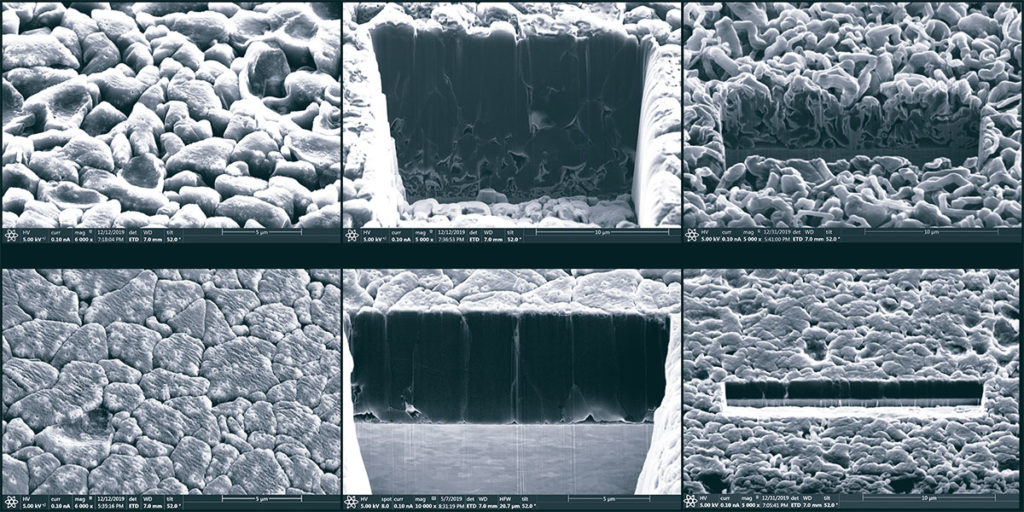

In a new study, the researchers from the University of California San Diego used several characterizations and imaging techniques to study LMB morphology and quantify performance when the batteries were subjected to different pressures. They found that higher pressure levels of 350 kilo Pascal (roughly 3.5 atmospheres) force lithium particles to deposit in neat columns without any porous spaces in between, leaving little space for dendrite formation. On the other hand, the batteries subjected to lower pressure levels are porous, and lithium particles deposit in a disorderly fashion, leaving room for dendrites to grow.

Researchers also showed that the process doesn’t affect the solid electrolyte interphase (SEI) structure of the batteries’ electrolytes.

“We not only answered this scientific question but also identified the optimum pressure needed,” said Shirley Meng, a professor in the UC San Diego Department of NanoEngineering and the paper’s senior author. “We also proposed new testing protocols for maximum LMB performance.”

The team has noted that manufacturing facilities for LMBs would have to be retooled for this new technique to be applied. Another way to boost performance is to not completely discharge the battery while it cycles. Instead, the researchers keep a reservoir of lithium where re-nucleation can occur.