Soft, elastic semiconductors and circuits could advance wearable medical devices and other emerging technologies. However, high-performance electronics are difficult and expensive to manufacture.

A research team led by Pennsylvania State University plans to make the process easier and cheaper with a new manufacturing method.

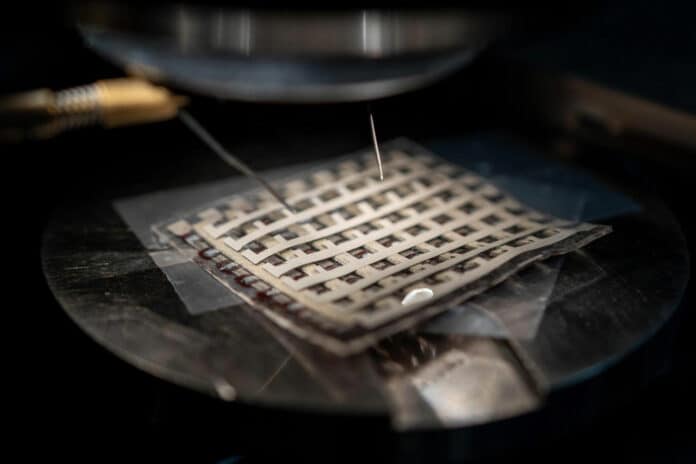

The new process is called the lateral phase separation-induced micromesh (LPSM) strategy. It involves mixing a semiconductor and an elastomer – or rubber – and spin coating the liquid mixture precursors to fabricate rubbery semiconductor thin films. The spin-coated film automatically triggers a lateral phase separation mechanism, which generates micromesh structures within seconds.

The micromesh materials are integral for allowing for mechanical stretch, according to Cunjiang Yu, Dorothy Quiggle Career Development Associate Professor of Engineering Science and Mechanics and associate professor of biomedical engineering and materials science and engineering. “The LPSM films used to create the stretchy semiconductors promise simultaneous efficient charge transport and mechanical stretchability,” Yu said.

The micromesh-structured rubbery semiconductors simultaneously provide efficient charge transport and mechanical stretchability. And by using different polymer blends, researchers create both p-type and n-type rubbery semiconductor films, whose majority charge carriers are holes and electrons, respectively.

Using both semiconductor types, according to Yu, researchers created soft electronic devices such as rubbery transistors, complementary inverters, and bilayer heterojunction photodetectors that can stretch to a large extent while maintaining functionality. In addition, the researchers created a rubbery bioelectronic device known as an epicardial patch that has an active transistor matrix and can be used to map the biopotentials of a rat heart.

“As the rat’s heart expanded and contracted with its heartbeat, the entirely rubber-based epicardial patch also moved with it,” Yu said. “We recorded multiple channels of electrophysiology readings simultaneously with the patch. Recording at multiple sites of the heart is important to identify cardiac problems such as arrhythmia.”

In future work, researchers hope to further optimize the LPSM process and investigate the detailed properties of the semiconductor materials. They also plan to employ the LPSM semiconducting thin film in various high-performance integrated electronics and functional systems.

Journal reference:

- Ying-Shi Guan, Faheem Ershad, Zhoulyu Rao, Zhifan Ke, Ernesto Curty da Costa, Qian Xiang, Yuntao Lu, Xu Wang, Jianguo Mei, Peter Vanderslice, Camila Hochman-Mendez and Cunjiang Yu. Elastic electronics based on micromesh-structured rubbery semiconductor films. Nature Electronics (2022); DOI: 10.1038/s41928-022-00874-z