Microplastics have been a persistent environmental problem, and it is now known that microplastics have permeated the terrestrial, freshwater, and marine ecosystems. Water treatment plants provide a viable solution for the removal of microplastics from the environment. However, until now, these plants have not been able to sufficiently filter out tiny microplastics in wastewater.

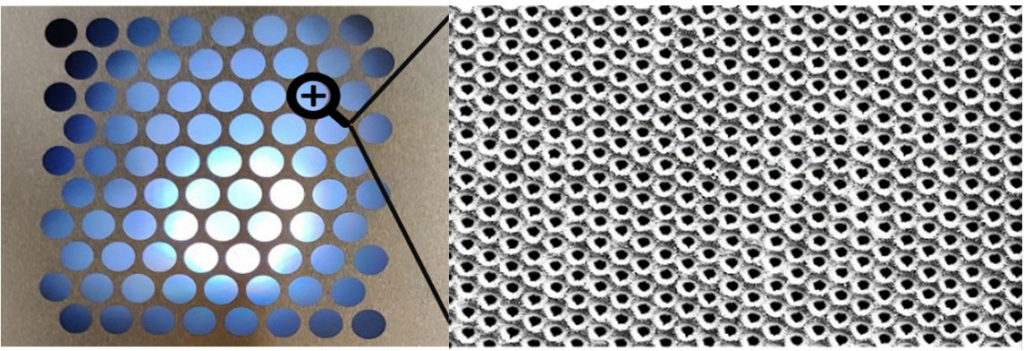

Now, engineers at the Fraunhofer Institute for Laser Technology (ILT) have developed the laser-drilled microplastic filter that – for the first time – can remove microplastics from wastewater. It contains sheets with millions of extremely small holes just 10 micrometers in diameter to stop the microplastics.

In the SimConDrill project, Fraunhofer ILT has joined forces with industrial partners to build a maintenance-free filter that stops microplastics in wastewater treatment. The challenge was to drill as many holes as possible, as small as possible, in a steel foil in the shortest time possible, says project manager Andrea Lanfermann.

Fraunhofer ILT engineers used the multi-beam process – in which a matrix of identical beams is generated from a laser beam via a special optical system – with an ultrashort-pulse laser (TruMicro 5280 Femto Edition) to drill holes simultaneously with 144 beams.

In the first test, the fine powder from 3D printers was filtered from contaminated water. The setup is now being tested in a wastewater treatment plant under real conditions.

At the same time, a consortium of six partners is working on integrating such a multi-beam processing system into an industrial machine. In the EU project Multiflex, researchers along with the industry are increasing the productivity of scanner-based laser material processing using multi-beam processes. The project partners aim to increase the speed of the process by a factor of twenty to fifty, thus making the entire process significantly more cost-effective.