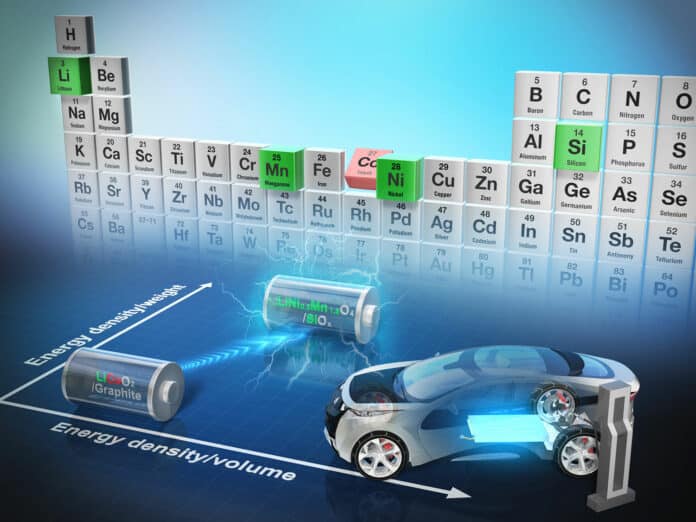

High-capacity lithium-ion batteries (LIBs) to power electric vehicles play an increasingly important role in the transition to a carbon-neutral transportation system. LIBs can survive a large number of recharge cycles, but they also degrade with time; it would be better for everyone if batteries could survive more recharge cycles and maintain their capacities for longer. But perhaps the most alarming problem with current LIBs lies in one of the elements used for their construction.

At present, the chemistry of LIBs requires, among other elements, cobalt (Co), the production of which contributes to some environmental, economic, and social issues. Therefore, finding alternative chemistries for LIBs that can reduce or eliminate the need for Co is a major challenge and opportunity for sustainable mobility.

A new study involving researchers from the University of Tokyo proposes a viable alternative to cobalt, which, in some ways, can outperform state-of-the-art battery chemistry. The new chemistry also has a long cycle life and can be used to solve other battery-related challenges.

“There are many reasons we want to transition away from using cobalt in order to improve lithium-ion batteries,” said Professor Atsuo Yamada from the Department of Chemical System Engineering. “For us, the challenge is a technical one, but its impact could be environmental, economic, social, and technological. We are pleased to report a new alternative to cobalt by using a novel combination of elements in the electrodes, including lithium, nickel, manganese, silicon, and oxygen – all far more common and less problematic elements to produce and work with.”

Yamada and his team created new electrodes and electrolytes that are not only cobalt-free but actually improve upon current battery chemistry in some ways. According to researchers, the new LIBs’ energy density is about 60% higher, which could equate to longer life, and it can deliver 4.4 volts, as opposed to about 3.2-3.7 volts of typical LIBs. But one of the most surprising technological achievements was to improve upon the recharge characteristics.

Moreover, they have a longer lifespan, as they can withstand over 1,000 charge and discharge cycles whilst only losing about 20% of their storage capacity.

“We are delighted with the results so far, but getting here was not without its challenges. It was a struggle trying to suppress various undesirable reactions that were taking place in early versions of our new battery chemistries, which could have drastically reduced the longevity of the batteries,” said Yamada. “And we still have some way to go, as there are lingering minor reactions to mitigate in order to improve the safety and longevity even further. At present, we are confident that this research will lead to improved batteries for many applications, but some, where extreme durability and lifespan are required, might not be satisfied just yet.”

Although Yamada and his team were exploring applications in LIBs, the concepts that underlie their recent development can be applied to other electrochemical processes and devices, including other kinds of batteries, water splitting (to produce hydrogen and oxygen), ore smelting, electro-coating, and more.