Hydrogen mobility technologies are emerging as one of the promising solutions to achieve carbon neutrality in the transportation sector. Now, researchers in South Korea have developed a new technology for a 2-liter class hydrogen-fueled engine capable of running entirely on hydrogen.

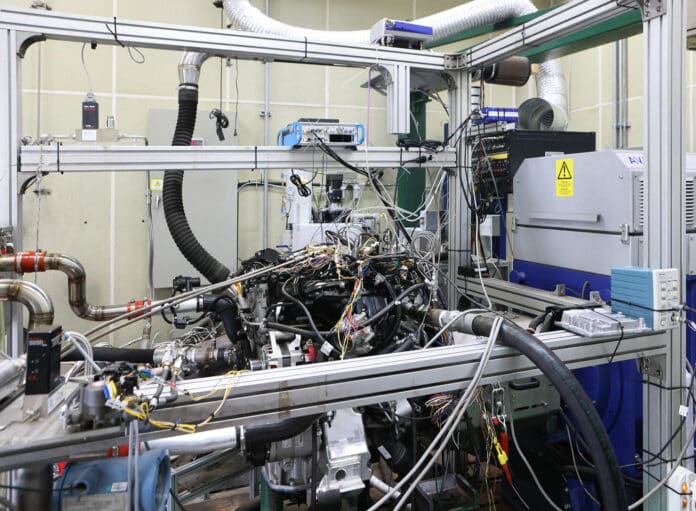

The new “direct injection hydrogen engine” is jointly developed by researchers at the Korea Institute of Machinery and Materials (KIMM) and the Zero-Carbon Engine Research Lab of Hyundai-Kia Motor Company (HMC).

For their study, the researchers have injected hydrogen directly into the combustion chamber of HMC’s existing hybrid vehicle. The hydrogen was injected at a pressure of more than 30 bar, which is more than 30 times the atmospheric pressure.

The research team used a turbocharger to improve the performance of the engine, which allowed for high thermal efficiency in all domains, from the ignition of the engine to the upper limit of the engine load. As a result, the engine was able to be stably operated throughout all engine operating conditions.

In the conventional “port injection hydrogen engines” – a type of internal-combustion engine that uses hydrogen as fuel, the presence of hydrogen fuel in a gaseous state takes up space in the combustion chamber. This results in a decrease in the amount of air that flows into the chamber, which reduces fuel efficiency and engine performance due to the backfire of the hydrogen fuel and air.

The newly developed “direct injection hydrogen engine” resolves the issue of backfire by injecting high-pressure hydrogen fuel directly into the combustion chamber. Additionally, the engine features a high compression ratio, fuel stratification, and ultra-lean combustion that can maximize thermal efficiency and enhance power performance while reducing harmful emissions.

The new hydrogen engine is more environmentally friendly than gasoline engines, as it can reduce carbon dioxide and fine dust emissions by 99% and 90%, respectively. This meets the European Union’s requirements for zero-emission vehicles. Furthermore, this type of engine emits nitrogen oxides of less than 15 ppm even without an after-treatment system, which purifies exhaust gases while achieving a high thermal efficiency of up to 40%.

“Through collaboration with HMC, we will verify the durability of the engine and also expand the application of this technology to not only passenger vehicles but also commercial vehicles and electricity generation power units,” said Young Choi, principal researcher and part of the Department of Mobility Power Research of KIMM, in a statement. “Through continuous research and development of technologies for generating power using carbon-free fuels, we will take the lead in the realization of carbon neutrality.”