GE Aerospace has secured a new contract from NASA for Phase 2 of the Hybrid Thermally Efficient Core (HyTEC) program. The program supports continued technology development for the next generation of commercial aircraft engines with the aim to improve fuel efficiency significantly and reduce emissions compared to engines today.

As part of the NASA Advanced Air Vehicles Program (AAVP), the HyTEC Project was established to accelerate the development of small turbofan engine core technologies to enable fuel burn reductions, additional use of electric airplane systems through power extracted from the engine, and advance engine operability and compatibility with sustainable aviation fuels.

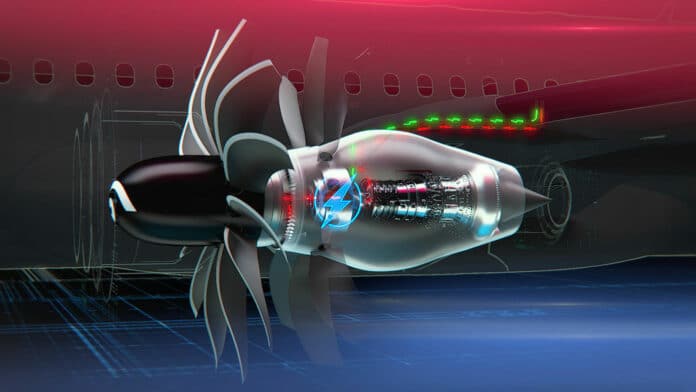

The new contract builds on work completed in Phase 1 of HyTEC for developing advanced aerodynamics for the high-pressure compressor, high-pressure turbine, and combustor, which are the key components of the engine core. These components compress, burn, and expand the air-fuel mixture that generates thrust.

In Phase 2, GE Aerospace will continue to refine these technologies and test them in a core demonstrator test later this decade. Testing will also expand to evaluate 100% Sustainable Aviation Fuel (SAF) combustion to reduce emissions.

Also, GE Aerospace will be working on further advancing the state-of-the-art engine integration of hybrid electric systems. Hybrid electric testing under HyTEC Phase 2 builds on GE Aerospace’s ongoing efforts to develop more electric engines, including the previously awarded NASA Turbofan Engine Power Extraction Demonstration under the first phase of HyTEC.

Phase 2 of the program is a major demonstration within NASA’s Sustainable Flight National Partnership portfolio that will contribute to the U.S. goal of net-zero greenhouse gas emissions by 2050.

“We are grateful and proud to collaborate with NASA to invent the future of flight. With the HyTEC program, GE Aerospace looks to further advance aircraft engine core technologies beyond our current industry-leading propulsion systems for a once-in-a-generation improvement in fuel efficiency,” said Mohamed Ali, vice president of engineering for GE Aerospace.

GE Aerospace is currently involved in executing an ambitious technology demonstration roadmap, which is one of the most comprehensive in the industry. As part of CFM International’s RISE (Revolutionary Innovation for Sustainable Engines) program, more than 100 tests have been completed to develop new aviation engine technology that will increase propulsive and thermal efficiency. These include open fan engine architecture and engine compact core work supported by HyTEC.

The RISE program aims to achieve more than 20% improved fuel efficiency and 20% fewer CO2 emissions by the mid-2030s than today’s most efficient engines. All GE Aerospace and CFM International engines can operate on approved SAF blends, and new technologies are being developed to make them compatible with alternative energy sources, including 100% SAF. In fact, GE Aerospace and its joint ventures have already tested ten different aircraft engine models with 100% SAF through a mix of component-, engine-, and aircraft-level studies.