In collaboration with Hong Kong Polytechnic University and Hexagon Manufacturing Intelligence Company in Melbourne, researchers from RMIT University and the University of Sydney have developed a 3D-printed strong and ductile titanium alloy that contains low-cost and abundant oxygen and iron as a principal alloying element.

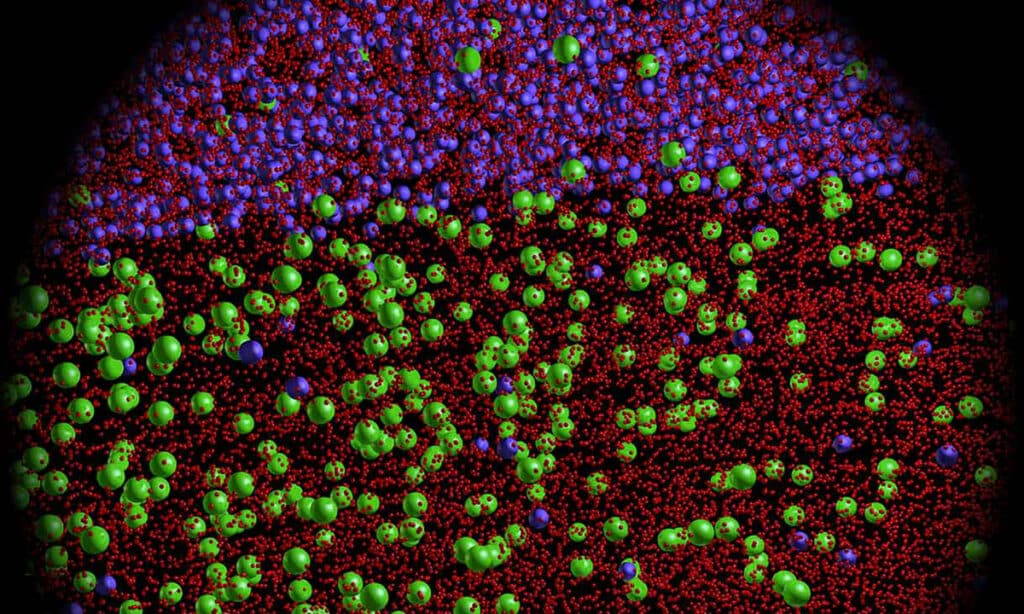

The researcher’s titanium alloys consist of a mixture of two types of titanium crystals, called the alpha-titanium phase and the beta-titanium phase, each associated with a specific arrangement of atoms. These alloys have been produced primarily by adding aluminum and vanadium to titanium.

The research team explored the use of oxygen and iron. These two of the most powerful stabilizers and strengtheners of alpha- and beta-titanium phases are abundant and inexpensive.

The researchers found that two challenges hindered the development of strong and ductile alpha-beta titanium-oxygen-iron alloys through conventional manufacturing processes, the first challenge being that oxygen is described as the ‘kryptonite to titanium’ and can make titanium brittle. Secondly, the addition of iron can cause severe defects in the form of large patches of beta-titanium.

The combination of the team’s alloy design concepts with the 3D-printing process is the design was the key enabler for the researchers, which has identified a range of alloys that are strong, ductile, and easy to print.

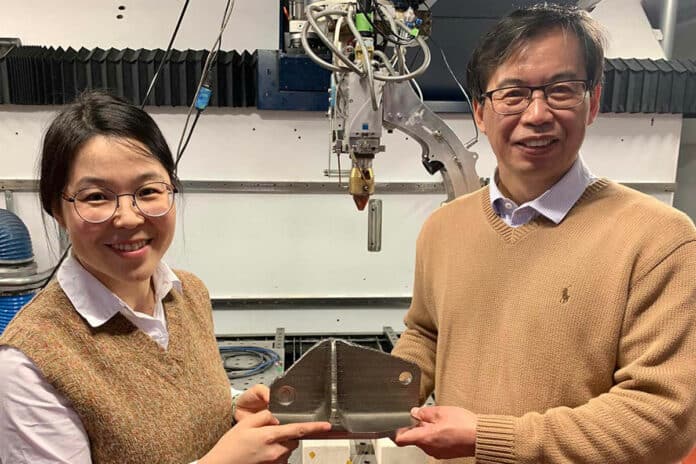

Researchers used Laser Directed Energy Deposition (L-DED), a 3D printing process suitable for making large, complex parts, to print their alloys from metal powder.

The attractive properties of these new alloys can rival commercial alloys are attributed to their microstructure.

“This research delivers a new titanium alloy system capable of a wide and tunable range of mechanical properties, high manufacturability, enormous potential for emissions reduction, and insights for materials design in kindred systems,” said Professor Simon Ringer, co-lead researcher, and University of Sydney Pro-Vice-Chancellor.

“We’ve engineered a nanoscale gradient of oxygen in the alpha-titanium phase, featuring high-oxygen segments that are strong and low-oxygen segments that are ductile, allowing us to exert control over the local atomic bonding and so mitigate the potential for embrittlement,” said, Professor Simon Ringer.

These research findings can be potentially used in various applications such as to reuse waste sponge titanium-oxygen-iron alloy, ‘out-of-spec’ recycled high-oxygen titanium powders, or titanium powders made from high-oxygen scrap titanium using this approach. This research also may provide a template to mitigate these oxygen embrittlement issues through 3D printing and microstructure design.

Reusing waste and low-quality materials has the potential to add economic value and reduce the high carbon footprint of the titanium industry.

The Australia Research Council (ARC) funded and supported this research through the Discovery Program and the Training Centre in Surface Engineering for Advanced Materials (SEAM).

Journal reference:

- Tingting Song, Zibin Chen, Xiangyuan Cui, Shenglu Lu, Hansheng Chen, Hao Wang, Tony Dong, Bailiang Qin, Kang Cheung Chan, Milan Brandt, Xiaozhou Liao, Simon P. Ringer, and Ma Qian. Strong and ductile titanium–oxygen–iron alloys by additive manufacturing. Nature, 2023; DOI: 10.1038/s41586-023-05952-6

- Designer titanium alloys created using 3D printing. Nature, 2023; DOI: 10.1038/d41586-023-01360-y