Sustainable aviation fuel (SAF) is essential to decrease the carbon footprint of the aviation industry. However, due to their lack of aromatic molecules, they require blending with conventional fuels to achieve the necessary characteristics for their safe use.

Now, a team of researchers – from the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), the Massachusetts Institute of Technology (MIT), and Washington State University – has reported success in using lignin as a path toward a drop in 100% sustainable aviation fuel.

Lignin is an abundant, renewable biopolymer that has traditionally been underutilized due to its chemical recalcitrance. This organic polymer makes up the rigid parts of the cell walls of plants. Other parts of plants are used for biofuels, but lignin has been largely overlooked because of the difficulties in breaking it down chemically and converting it into useful products.

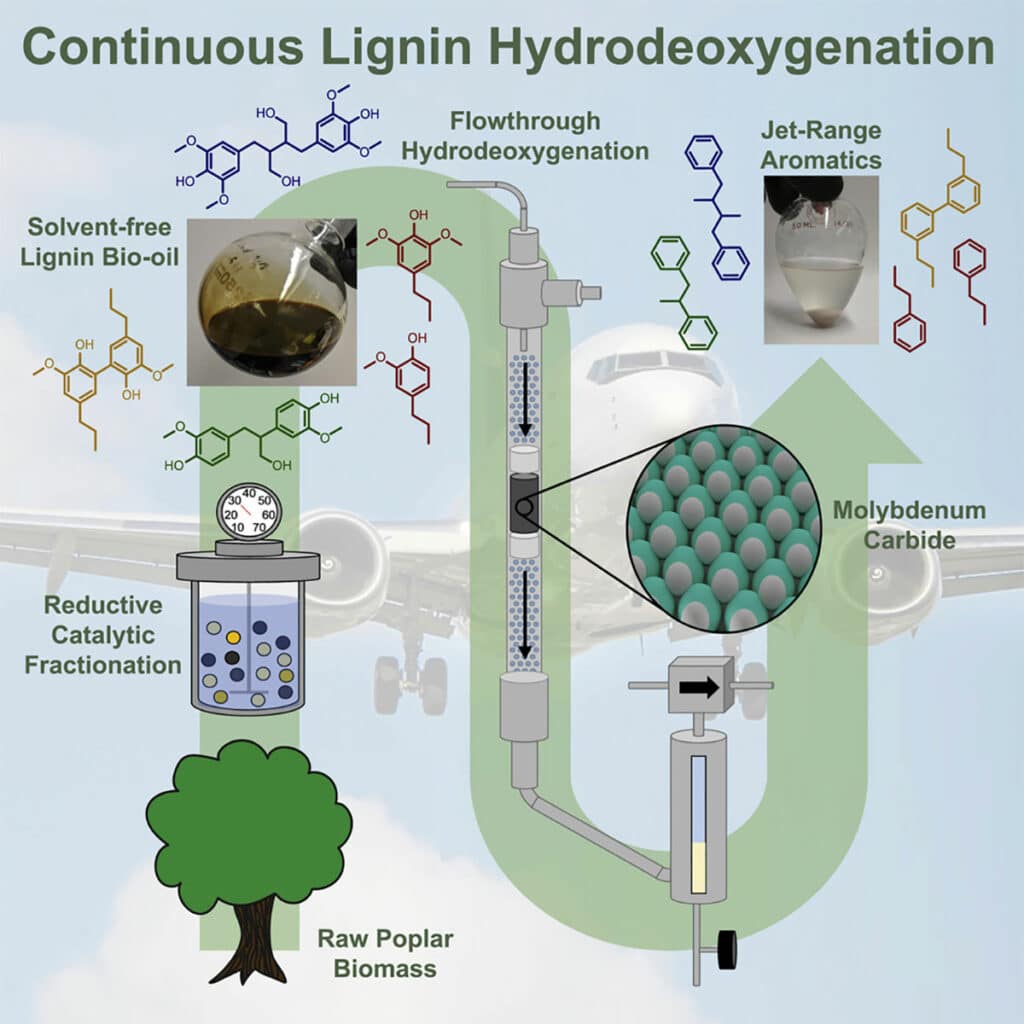

Now, researchers have developed a process to remove the oxygen from lignin such that the resulting hydrocarbons could be used as a jet fuel blendstock.

Jet fuel is a blended mixture of different hydrocarbon molecules, including aromatics and cycloalkanes. Current commercialized technologies do not produce those components to qualify for a 100% SAF. As the largest source of renewable aromatics in nature, lignin could hold the answer to achieving a complete bio-based jet fuel. H however, major challenges in deoxygenation have prevented its use as a feedstock for SAFs.

The new work demonstrates a process by which lignin can be selectively converted to jet-range aromatics at unprecedented carbon yields, providing a path toward a 100% drop in SAF. In the paper, researchers report a continuous, two-stage catalytic process using molybdenum carbide to deoxygenate lignin from poplar into aromatic hydrocarbons with 87.5% selectivity toward aromatic hydrocarbons at 86% of the theoretical carbon recovery.

Lignin is typically burned for heat and power or used only in low-value applications because of its recalcitrance. Previous research has yielded lignin oils with high oxygen contents ranging from 27% to 34%, but to be used as jet fuel, that amount must be reduced to less than half-percent.

In previous research, other processes have been tried to reduce the oxygen content, but the catalysts involved require expensive noble metals and proved to be low yielding. The team of researchers demonstrated an efficient method that used earth-abundant molybdenum carbide as the catalyst in a continuous process, achieving an oxygen content of about 1%.

Journal reference:

- Michael L. Stone, Matthew S. Webber, William P. Mounfield, David C. Bell, Earl Christensen, Ana R.C. Morais, Yanding Li, Eric M. Anderson, Joshua S. Heyne, Gregg T. Beckham, Yuriy Román-Leshkov. Continuous hydrodeoxygenation of lignin to jet-range aromatic hydrocarbons. Joule, 2022; Doi: 10.1016/j.joule.2022.08.005