Solar panels, one of the purest and most reliable methods for producing renewable energy, aren’t just for rooftops anymore. Some buildings even have these power-generating structures all over their facades. As more buildings and public spaces incorporate photovoltaic technologies, their monotonous black color could leave people underwhelmed. Great efforts are required to make photovoltaic (PV) panels aesthetically pleasing.

Now, a team of Chinese researchers has created solar panels that take on colorful hues while producing energy nearly as efficiently as traditional ones.

Solar panels are typically a deep black color because their job is to absorb light. Giving these devices different colors tends to minimize power generation ability and light absorption. One alternative is to use structural sources of color that take advantage of microscopic shapes to only reflect a very narrow, selective portion of light, like the scales on butterfly wings.

However, previous technologies that attempted incorporation of such color tech gave panels an undesirable iridescence or were expensive to implement at a large scale.

The Chinese researchers are working to develop a way of giving solar panels color using a structural material that would be easy and inexpensive to apply and that would maintain their ability to produce energy efficiently. The team sprayed a thin layer of a material called a photonic glass – which is made of a thin, disorderly layer of dielectric microscopic zinc sulfide spheres – onto the surfaces of solar cells.

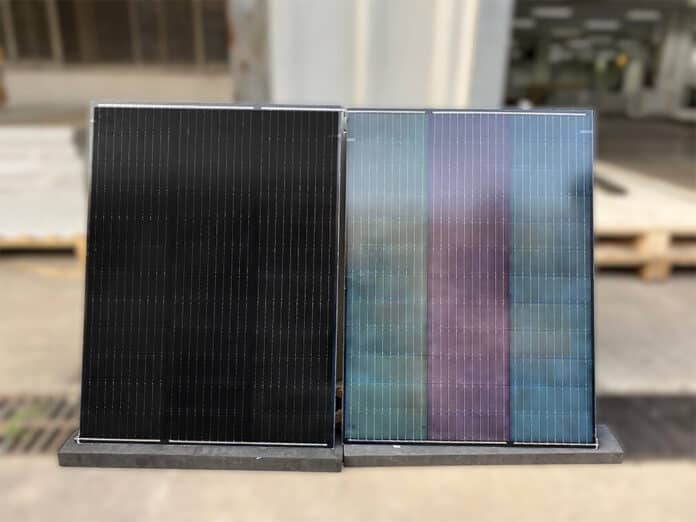

Although most of the light could pass through the photonic glass, selective colors were reflected back based on the sizes of the spheres. Using their new approach, the researchers created solar panels that took on blue, green, and purple hues while only dropping the efficiency of power generation from 22.6% to 21.5%. In addition, they found that the solar panels manufactured with this photonic glass layer maintained their color and performance during standard durability tests, and the fabrication could be scaled up.

Next, the team plans to explore ways to make the colors more saturated and methods to achieve a wider range of colors.