University of California San Diego engineers have developed wireless, battery less electronic stickers that measure the force exerted by one object on another. Its design is really simple with minimal electronics.

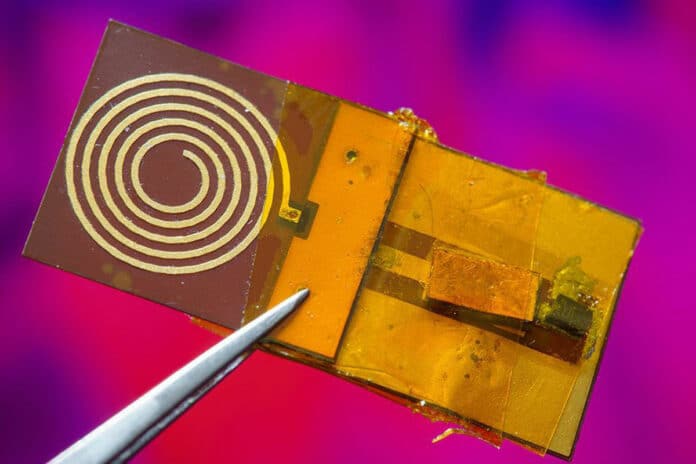

Force stickers have two main components:

- A capacitor that is just a few millimetres thin.

- Radio frequency identification (RFID) sticker, which is a device that acts like a barcode that can be read wirelessly using a radio signal.

The researchers found a clever way to integrate these two components together so that they can measure the force applied by the object and wirelessly communicate that information to the RFID reader.

The capacitor is made of a soft polymer sheet inserted between two conductive copper strips. When an external force is applied, the polymer compresses, drawing the copper strips closer together and increasing the capacitor’s electrical charge.

The researchers showed that this increase in electric charge due to the applied force is important, as it changes the signal transmitted by the RFID sticker. An RFID reader measures these changes remotely and translates them into a specific magnitude of applied force.

This unique technique of modifying the RFID signal enables the miniaturization of components in the force sticker. In comparison, previous methods of modifying RFID signals required components thousands of times larger.

Meanwhile, the RFID sticker operates at very low power by transmitting radio signals through backscattering. It receives radio signals from the RFID reader, modifies the signal through electrical changes induced by the capacitor, and then reflects the modified signals back to the reader, which decodes and translates them into applied power.

As a result, the force sticker runs on essentially no power. The force stickers are wireless, run without batteries, and fit in tight spaces.

Another interesting feature of its design: Its capacitor can be customizable for different power ranges. The capacitor can be adjusted to measure smaller or larger forces, respectively, by switching out the polymer layer for one that is softer or stiffer

It can be used to enhance the immersive experience of VR and AR, make biomedical devices smarter, monitor the safety of industrial equipment, and arm robots with a sense of touch to improve the accuracy and efficiency of inventory management in warehouses.

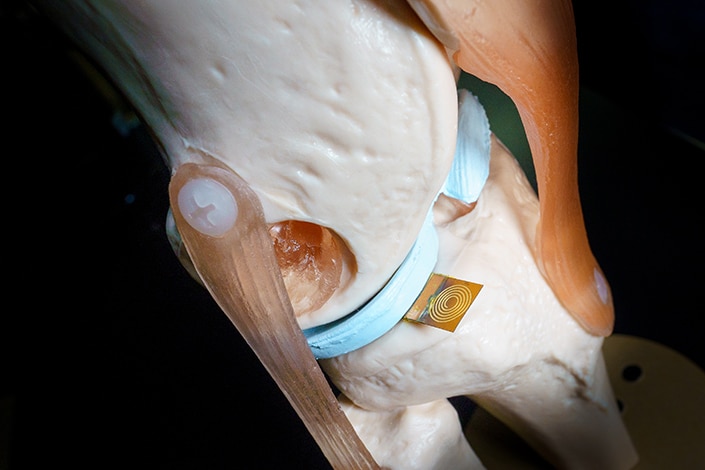

For example, in knee implants, force stickers can be used to measure the forces the implant exerts on the joint.

“These force stickers could make technology more intelligent, interactive, and intuitive,” said Dinesh Bharadia, professor of electrical and computer engineering at the UC San Diego Jacobs School of Engineering.

“Humans, by nature, possess an inherent ability to sense force. This allows us to interact seamlessly with our surroundings and enables clinicians to perform delicate surgical procedures. Providing this force-sensing ability to electronic devices and medical implants could be a game-changer for many industries.”

To demonstrate, the researchers created and tested two types of force stickers. In one sticker, capacitors for small force measurements were made with super soft polymers, making them suitable for model knee joint experiments. When force stickers are placed inside the joint, the force sticker accurately measures different applied forces as the researchers push on the joint.

Another sticker, in which the capacitor was bound with a stiffer polymer, was tested in a warehouse packaging experiment. Attached to the bottom of the box, it accurately measures the weight of different quantities of items placed in the box.

Researchers found that these force stickers were highly durable. They have withstood over 10,000 force applications and remained consistently. Additionally, researchers noted that these stickers can be produced accurately at a low cost, with each sticker costing less than $2.

“If we can commercialize this technology, we imagine that in the future, a box of them could be sold inexpensively, like a box of Band-Aids,” said Gupta.

The researchers aim to make Force stickers readable by smartphones, eliminating the need for RFID readers.