The transportation industry is undergoing a major transformation with the rise of advanced air mobility (AAM), with hundreds of new eVTOL concepts ready to demonstrate their abilities soon.

While other AAM companies are focusing on certification requirements and flight tests, CycloTech, an Austrian manufacturer, broke an industry record with the most extensive CycloRotor outdoor noise test campaign ever conducted in the aeronautical industry.

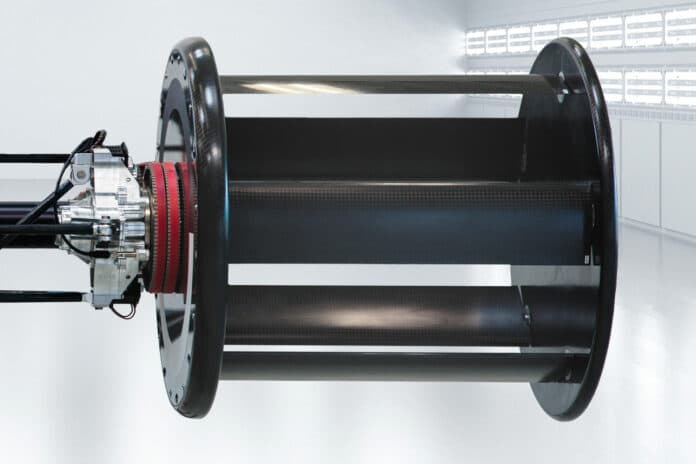

CycloRotor has become a new propulsion option for urban air mobility vehicles, offering a unique 360-degree thrust vectoring capability coupled with a compact design. The company is still refining this propulsion concept, including the aeroacoustic signature. It will eventually be integrated into future electric vehicles, including air taxis and cargo drones.

Although revolutionary, the technology is based on the principle of the Voith-Schneider-Propeller, successfully applied for decades for highly agile and stable ships in the maritime industry.

CycloRotors are thrust-vector systems that enable an immediate thrust generation 360-degree around the rotation axis – at constant rotation speed and direction – within fractions of a second.

Back in 2021, CycloTech kicked off indoor flight tests using an 83-kg (183 lb) demonstrator equipped with four CycloRotors. The company says it has completed more than 100 flights with this particular prototype so far.

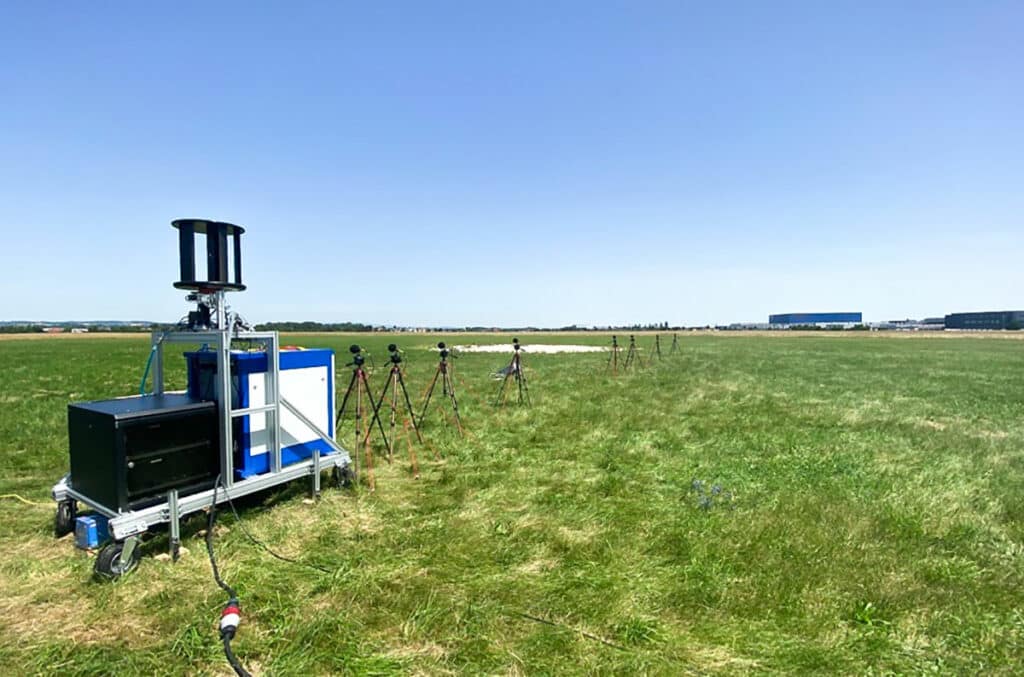

The latest noise test campaign was conducted at Wels General Aviation Airport, Austria. It came after CycloTech received permission from Austro Control, the Austrian aviation safety authority, to perform outdoor flight tests in specific conditions.

The data gathered from the test campaign are used to investigate the influence of different parameters on the acoustic characteristics of CyloRotors. It is also used to guide the design of CycloRotor-driven AirCar concepts in order to leverage the noise reduction potential of electrically powered air vehicles and thus minimize noise exposure in populated areas.

During the tests, the CycloRotor CR-42 was mounted vertically on a mobile frame and placed far away from any reflective surface. The CycloTech team performed measurements in moments of no air traffic and wind speeds below 2.5m/s. Eight microphones were arranged in five distinct configurations to characterize the noise generation and propagation of the CycloRotor.

The unprecedented test campaign revealed that the CycloRotor generates a sound pressure level of 59 dBA at a distance of 100 meters, which is equivalent to the level of a typical conversation between two people.

“This is a promising result, and CycloTech will continue to investigate and optimize the aeroacoustic signature of the CycloRotor,” said Pedro Carrasco Laraña, Aeroacoustics Engineer at CycloTech.