Hydrogen can make a big difference to our carbon emissions. It can be an eco-friendly alternative to fossil fuels as it releases water when burned. Hydrogen demand is expected to increase by 138% by 2030. However, high production costs and energy input are the main challenges for green hydrogen production.

Australia’s national science agency, CSIRO, corporate and advisor RFC Ambrian has co-founded Hadean Energy. The new company has developed a low-cost Tubular Solid Oxide Electrolysis (tSOE) technology that has higher efficiencies than existing technologies such as polymer electrolyte membranes (PEM) and alkaline electrolysis.

CSIRO will test the tSOE technology at BlueScope’s Port Kembla steelworks to demonstrate the equipment at a pilot scale in an industrial environment.

Solid oxide electrolysis (SOE) is the most efficient method when integrated with industrial heat waste. This technology converts steam into hydrogen and oxygen in an electrochemical reaction using a ceramic electrolyte.

“It allows industrial waste heat to be integrated back into the industrial processes, which decreases the electrical energy required to produce hydrogen or syn-gas by up to 30 percent.”

“It’s great news for industry because integrating the hydrogen product back into industrial processes onsite also eliminates storage and transport costs while drastically reducing the use of fossil fuels in the industrial process,” said Dr. Giddey, lead scientist on hydrogen research at CSIRO.

SOE uses ceramic cells to split heated steam molecules into hydrogen and oxygen. SOE operates at temperatures above 800°C, using excess heat from industrial processes to make the cell conductive. This heat reduces the electricity required for the reaction by 30% compared to PEM and alkaline electrolysis, significantly reducing electricity costs. Synthesis gas can also be produced by a similar process in an SOE electrolyzer.

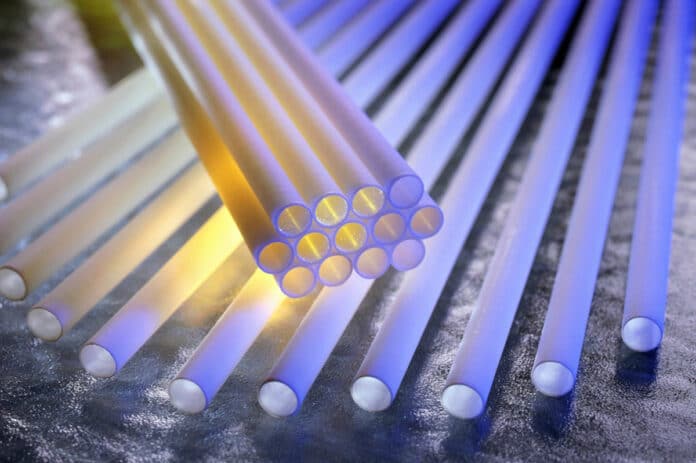

Hadean’s tubular solid oxide cell structure reduces cost and complexity while increasing repair capability. Its cell materials and configurations simplify low-cost manufacturing processes, supporting rapid, scalable production. The tubular structure reduces sealing requirements and improves safety and stack longevity. The company’s new cell design improves cell durability and avoids high-cost critical minerals.

The tSOF technology also allows operational flexibility with a fully reversible design made possible by the symmetrical cell configuration. This will enable the technology to be equally suitable for combined heat and power (CHP) applications.

Hydrogen and syn-gas are established feedstocks for producing chemicals and fuels. The technology has wide applications in industries including steel, ammonia, petrochemicals, methanol, and heavy transportation. The technology can be used directly in industries where processes demand hydrogen, eliminating the cost and technical challenges of storing and transporting hydrogen on a large scale.

Tubular solid oxide electrolysis (SOE) technology efficiently produces hydrogen by electrolyzing water using a combination of heat and electricity. It promises to significantly reduce hydrogen production costs and industry emissions through process efficiency.

CSIRO is testing with BlueScope will begin in April 2024. Integration aspects and other findings from testing will help demonstrate the technology at a higher level and confirm the technical robustness of the equipment.