As climate change intensifies and manifests itself in the form of record-setting natural disasters such as heatwaves and floods in recent years, there is a major impetus to reduce the greenhouse gases in the atmosphere. Nature contributes to this goal by converting carbon dioxide into biomass and sequestering 40 – 250 million tons of carbon in the soil and water bodies through forest fires every year. This alone, however, is insufficient to avert climate change.

To incentivize carbon sequestration activities, kraft paper, a renewable and recyclable bioproduct that is already manufactured at scale, is proposed as feedstock for producing economically viable carbon materials. Researchers from Nanyang Technological University, Singapore (NTU Singapore) have developed a technique to convert waste paper from single-use packaging and bags, and cardboard boxes, into a crucial component of lithium-ion batteries.

Using the process called carbonization, the NTU researchers turned the paper’s fibers into electrodes, which can be made into rechargeable batteries that power mobile phones, medical equipment, and electric vehicles.

To carbonize the paper, the NTU researchers first joined and laser cut several thin sheets of kraft paper to form different lattice geometries. The paper was then heated to 1200 degrees Celsius in a furnace without the presence of oxygen to convert it into carbon, forming the anodes.

As carbonization takes place in the absence of oxygen, this emits negligible amounts of carbon dioxide, and the process is a greener alternative to disposing of kraft paper through incineration, producing large amounts of greenhouse gasses. The carbon anodes produced by the research team also demonstrated superior durability, flexibility, and electrochemical properties.

Laboratory tests showed that the anodes could be charged and discharged up to 1,200 times, which is at least twice as durable as anodes in current phone batteries. According to the researchers, the batteries that use the NTU-made anodes could also withstand more physical stress than their counterparts, absorbing crushing energy up to five times better.

The NYU-developed method also used less energy-intensive processes and heavy metals compared to current industrial methods of manufacturing battery anodes. As the anode is worth 10% to 15% of the total cost of a lithium-ion battery, this latest method is expected to also bring down the cost of manufacturing them.

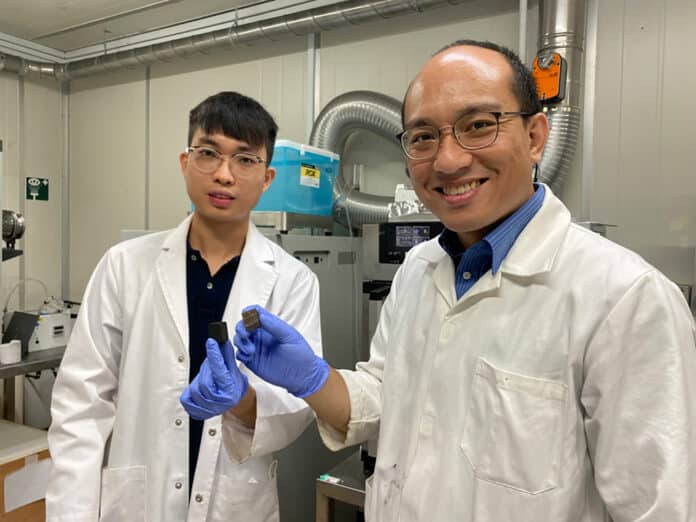

“Our method converts a common and ubiquitous material – paper – into another that is extremely durable and in high demand,” said Assistant Professor Lai Changquan, who led the project. “We hope that our anodes will serve the world’s quickly growing need for a sustainable and greener material for batteries, whose manufacturing and improper waste management have shown to have a negative impact on our environment.”

Next, the NTU team plans to conduct further research to improve the energy storage capacity of their material and minimize the heat energy required to convert paper into carbon.

Journal reference:

- Chang Quan Lai, Guo Yao Lim, Kai Jie Tai, Kang Jueh Dominic Lim, Linghui Yu, Pawan K. Kanaujia, Peiyuan Ian Seetoh. Exceptional energy absorption characteristics and compressive resilience of functional carbon foams scalably and sustainably derived from additively manufactured kraft paper. Additive Manufacturing, 2022; DOI: 10.1016/j.addma.2022.102992