Carbon dioxide is the main greenhouse gas warming Earth and is emitted in large quantities in the flue gas from industrial and power plants.

Berkeley scientists have created a cheap, easy, and energy-efficient way to capture carbon dioxide from smokestacks, a key goal for the United States and other nations as they seek to reduce greenhouse gas emissions.

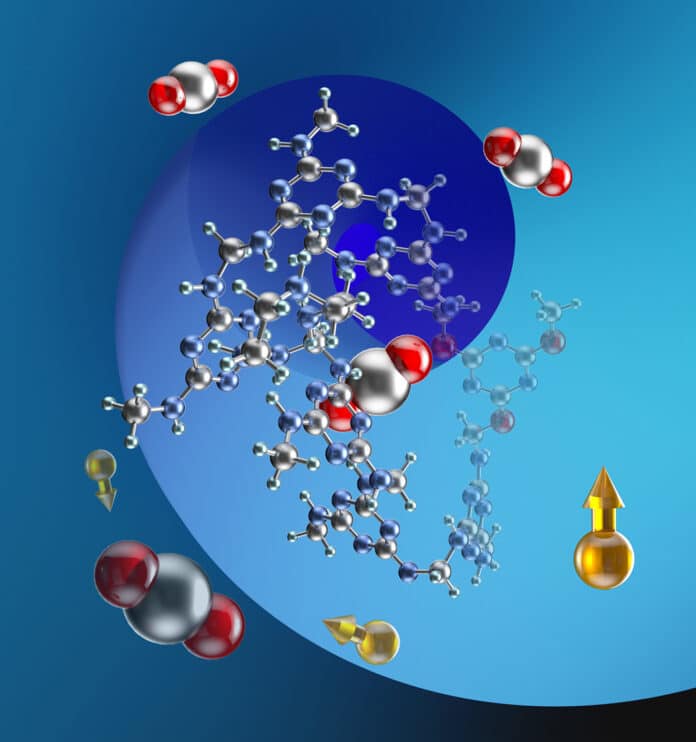

The new material developed by the researchers is simple to make, requiring primarily off-the-shelf melamine powder along with formaldehyde and cyanuric acid, a chemical that, among other uses, is added with chlorine to swimming pools. The so-called melamine porous network captures carbon dioxide with an efficiency comparable to early results for another relatively recent material for carbon capture, metal-organic frameworks (MOFs).

Researchers said that melamine-based materials use much cheaper ingredients, are easier to make, and are more energy efficient than most MOFs. The low cost of porous melamine means that the material could be deployed widely.

“In this study, we focused on cheaper material design for capture and storage and elucidating the interaction mechanism between CO2 and the material,” said Haiyan Mao, a UC Berkeley postdoctoral fellow who is the first author of the paper. “This work creates a general industrialization method towards sustainable CO2 capture using porous networks. We hope we can design a future attachment for capturing car exhaust gas, or maybe an attachment to a building or even a coating on the surface of furniture.”

The lab tests confirmed that formaldehyde-treated melamine adsorbed CO2 somewhat, but absorption could be much improved by adding another amine-containing chemical, DETA (diethylenetriamine), to bind CO2. The team subsequently found that adding cyanuric acid during the polymerization reaction dramatically increased pore size and radically improved CO2 capture efficiency. This technique absorbed nearly all the carbon dioxide in a simulated flue gas mixture within about 3 minutes.

“What Haiyan and her colleagues were able to show with these elegant techniques is exactly how these groups intermingle, exactly how CO2 reacts with them, and that in the presence of this pore-opening cyanuric acid, she’s able to cycle CO2 on and off many times with capacity that’s really quite good,” said Jeffrey Reimer, one of the corresponding authors of the paper. “And the rate at which CO2 adsorbs is actually quite rapid, relative to some other materials. So, all the practical aspects at the laboratory scale of this material for CO2 capture have been met, and it’s just incredibly cheap and easy to make.”