Wind energy projects are moving forward at a steady pace, and with new innovations in low-cost wind turbines, the industry is poised for even more growth. Wind turbines keep getting bigger because bigger turbines harvest more energy more steadily. Each blade can be longer than a football field, and some offshore turbines even exceed the height of a 50-story building.

However, the sheer scale of these turbines can significantly increase costs at every step of the process. From materials to manufacturing, transport, logistics, construction, and maintenance, dealing with long blades, tall tower structures, and massive generators that have to live at the top of them can take a severe hit on the budget.

A Wyoming startup, Airloom Energy, backed by Bill Gates and headed by a Google veteran Neal Rickner, aims to revolutionize wind power by fundamentally rethinking the design that reduces the size and cost of wind turbines.

Airloom’s approach is quite different and innovative, as it makes everything much smaller and closer to the ground. It utilizes the same physics as a conventional horizontal-axis wind turbine (HAWT) but with a very different layout. According to the company, this novel approach results in a unique utility-scale wind power device that produces the same amount of power as a HAWT at a small fraction of the mass and cost.

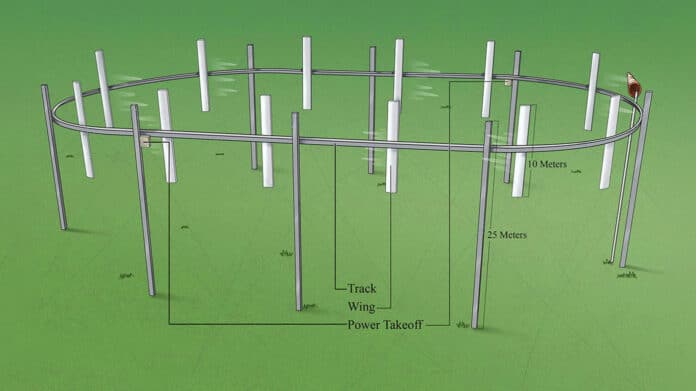

Unlike traditional wind turbines that mount massive blades on gigantic towers, Airloom’s 2.5-MW setup uses a number of 25-meter (82-foot) tall poles to suspend a lightweight oval-shaped track, into which 10-meter (33-foot) long blades are attached vertically. As the wind blows, the wings travel around the track and generate power.

The cost and environmental benefits of the Airloom extend throughout its entire lifecycle. The use of readily sourced materials and parts ensures quick manufacturing, the design is less than 10% of the cost of a traditional turbine, and it’s also less expensive to install. A full wind farm setup promises to be less than 25% of the capital cost required to build a conventional wind project.

In addition, the components of the new system can be delivered more easily. One standard tractor-trailer can transport an entire 2.5 MW Airloom, making it feasible to install wind power in remote or difficult locations.

Its height and length can be customized depending on landscape and use without requiring large concrete foundations during commissioning. The decrease in overall weight and materials also results in significantly less landfill waste at the end of its lifespan.

Moreover, Airloom’s equipment can be installed over agricultural land, allowing crops to grow underneath or next to roads where they can easily connect to the power grid. What sets it apart from traditional wind turbines is that it can produce more energy on the same amount of land, thanks to the fact that it doesn’t require as much spacing between turbines. Airloom claims its design will bring the Levelized Cost of Energy (LCoE) of wind energy down to as low as one-third of other wind power sources.

Another advantage of Airloom’s technology is that it could be safer for birds and bats than other wind turbines, although Airloom has yet to complete its environmental impact studies. The system also has a lower visual impact than other wind farms, as they are closer to the ground and less noticeable.

It’s worth noting that Airloom’s new wind turbine can be configured vertically or horizontally and that it can be deployed offshore as well as on land.

“For decades, the wind industry has lowered the cost of energy production by scaling ever larger turbines. Although this has been extremely successful in driving down overall costs, the approach now faces challenges in terms of both siting and cost of materials,” said Carmichael Roberts of Breakthrough Energy Ventures in a press release. “Airloom’s unique approach can solve both these problems, opening new market opportunities for wind energy that will further drive down costs. We look forward to Neal’s leadership in bringing this revolutionary technology into the market.”

With small-scale prototypes already up and running, the company plans to use its seed funding for research and development of the Airloom wind energy test device, which is designed to produce 50 kilowatts (kW) of electricity. Future systems are expected to be megawatt-scale and deployed hundreds of megawatts at a time in utility-scale wind farms.