Hydrogen is set to be pivotal in the transition to a clean-energy economy as it provides a high-energy density carrier for renewable energy. Green hydrogen is created through electrolysis, splitting water molecules into oxygen and hydrogen gases using renewable energy. This process produces green hydrogen, which represents just a small fraction of hydrogen production globally due to the high energy required. Most hydrogen is produced from splitting natural gas, known as blue hydrogen, which emits greenhouse gases into the atmosphere.

Researchers at the RMIT University in Australia have used sound waves to boost the production of green hydrogen by 14 times through electrolysis to split water. Their invention offers a promising way to tap into a plentiful supply of cheap hydrogen fuel for transportation and other sectors, which could radically reduce carbon emissions and help fight climate change.

In their experiment, the RMIT researchers used high-frequency vibrations to “divide and conquer” individual water molecules during electrolysis. Using these vibrations, the team managed to split the water molecules to release 14 times more hydrogen compared with standard electrolysis techniques.

“One of the main challenges of electrolysis is the high cost of electrode materials used, such as platinum or iridium,” said Associate Professor Amgad Rezk from RMIT University, who led the work. “With sound waves making it much easier to extract hydrogen from water, it eliminates the need to use corrosive electrolytes and expensive electrodes such as platinum or iridium. As water is not a corrosive electrolyte, we can use much cheaper electrode materials such as silver.”

The ability to use low-cost electrode materials and avoiding the use of highly corrosive electrolytes were game-changers for lowering the costs of producing green hydrogen, researchers say. The sound waves also prevented the build-up of hydrogen and oxygen bubbles on the electrodes, which greatly improved their conductivity and stability.

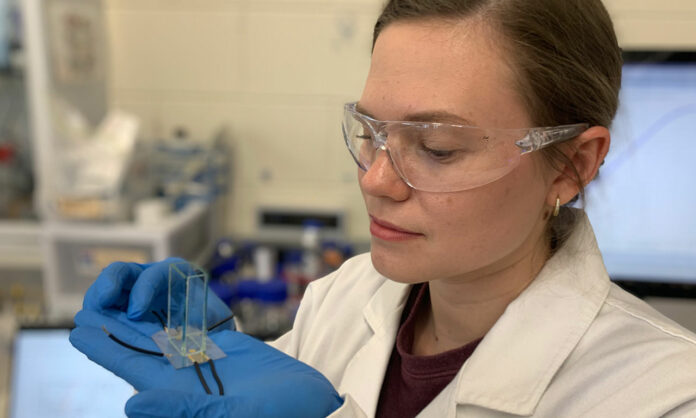

First author Yemima Ehrnst said Electrode materials used in electrolysis suffer from hydrogen and oxygen gas build-up, forming a gas layer that minimizes the electrodes’ activity and significantly reduces its performance. As part of their experiments, the team measured the amount of hydrogen produced through electrolysis with and without sound waves from the electrical output.

“The electrical output of the electrolysis with sound waves was about 14 times greater than electrolysis without them for a given input voltage. This was equivalent to the amount of hydrogen produced,” Ehrnst said.

The team’s breakthrough was a huge step towards using a new acoustic platform for other applications, especially where bubble build-up on the electrodes was a challenge.

“Our ability to suppress bubble build-up on the electrodes and rapidly remove them through high-frequency vibrations represents a major advance for electrode conductivity and stability,” said Professor Leslie Yeo, one of the lead senior researchers. “With our method, we can potentially improve the conversion efficiency leading to a net-positive energy saving of 27%.”

While the innovation is promising, the team needs to overcome challenges by integrating the sound-wave innovation with existing electrolyzers to scale up the work.

Journal reference:

- Yemima Ehrnst, Peter C. Sherrell, Amgad R. Rezk, and Leslie Y. Yeo. Acoustically-Induced Water Frustration for Enhanced Hydrogen Evolution Reaction in Neutral Electrolytes. Advanced Energy Materials, 2022; DOI: 10.1002/aenm.202203164