Singapore is considered to be one of the most water-stressed countries in the world. The Southeast Asian island nation has very limited natural water resources and has long had to rely principally on water supplies from neighboring Malaysia.

In a push for more self-sufficiency, the Singaporean government has developed a sophisticated sewage treatment system involving a network of tunnels and high-tech plants that can transform sewage into safe drinkable water while reducing ocean pollution.

While most recycled water is used for industrial purposes, some of it is added to drinking water supplies in reservoirs. And only a small amount of the treated water is discharged into the sea, which means the system also helps reduce maritime pollution.

“Singapore lacks natural resources, and it is limited in space, which is why we are always looking for ways to explore water sources and stretch our water supply,” Low Pei Chin, chief engineer of the Public Utilities Board’s water reclamation department, told AFP.

“Our water management strategy consists of three parts: first is to collect every drop of water, two, reuse endlessly, and thirdly is to turn seawater into drinking water, which is desalination,” she added.

At the heart of the recycling system is the high-tech Changi Water Reclamation Plant (Changi WRP), located on the city’s eastern coast. It is built partially underground and stacked for maximum compactness and land use. It consists of a maze of steel pipes, tubes, tanks, filtration systems, and other machinery and has the capacity to treat up to 237 million US gallons (900 million liters) of wastewater per day. It is fed by wastewater that flows through a massive, 48-kilometer tunnel linked to sewers.

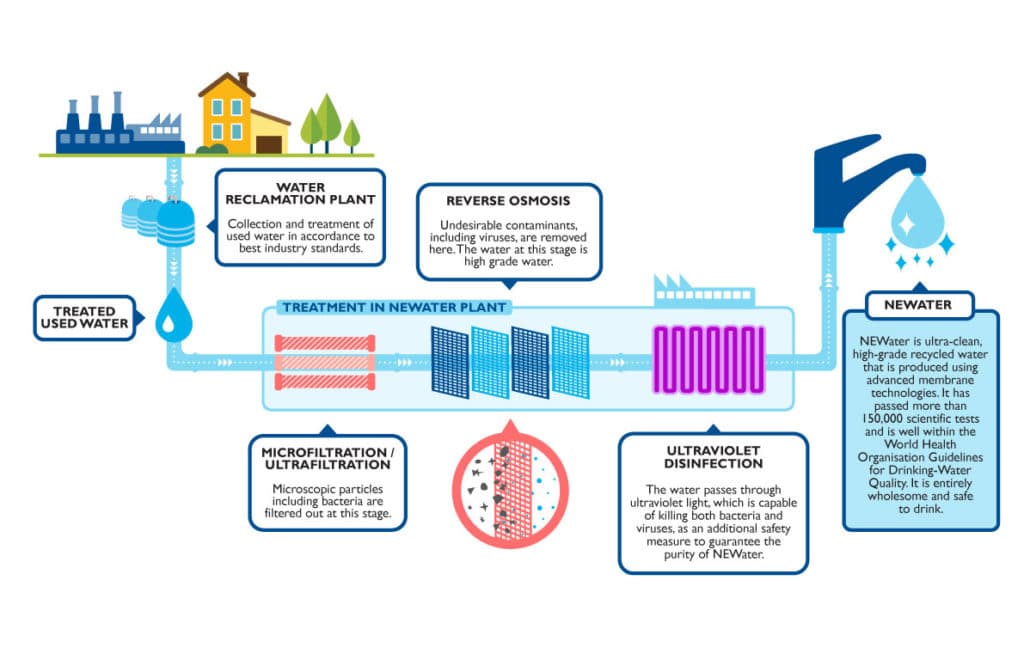

Changi WRP treats wastewater by effectively removing the solids and nutrients that are present in the wastewater. The treated water is then returned to the environment or transferred to NEWater factories for further processing.

At NEWater factories, the reclaimed water is purified further and made suitable for drinking using advanced membrane technologies. Impurities such as microscopic particles, bacteria, and viruses are removed and disinfected with ultraviolet rays. After adding some alkaline chemicals to restore the pH balance, NEWater is ready for use.

Currently, there are five NEWater plants supplying up to 40% of Singapore’s current water needs, and the figure is expected to go up to 55% by 2060.

This is not the end. Singapore is expanding its recycling system and plans to add an extra underground tunnel and construct a large water reclamation plant by 2025.