Electric cars have become very popular due to both less burning and less polluting environment. If nothing goes wrong, the future of the automotive is the electric car. But it is not as simple as replacing one engine with another and running. The current problem of electric motors is that they are custom designed, and if they are bought in small quantities, they are costly. This leaves small builders or unconventional car models out of play. That is where Swindon Powertrain’s attractive solution comes.

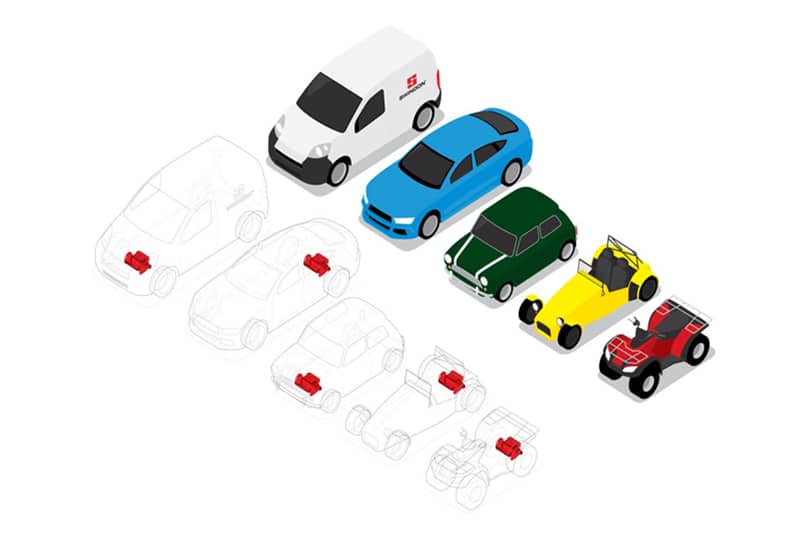

According to the British racing engine manufacturer, it has designed a universal electric motor that can be installed into a wide range of vehicle models: from quads, mini delivery cars to classic cars. In other words, it can transform any conventional vehicle into an electric one.

The company has been supplying engines to different brands since 1971, including official rally vehicles and speed tests, so it specializes in this field.

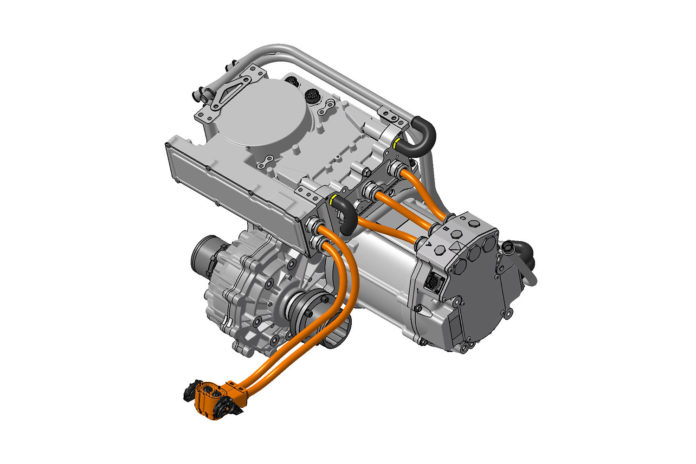

Swindon Powertrain is implementing the project together with e-motor manufacturer iNetic. The final product included motor, inverter, gearbox, and cooling system. The new 80kW (around 110hp) ‘crate’ powertrain weighs around 70 kilograms and measures 60 x 58.42 x 43.94 centimeters, enough to fit into the engine compartment of an original Mini or the chassis of a quad bike.

And with the option of the waterproof casing, the electric crate motor can be used on all terrains. Besides, since it occupies so little, it can also be used as a second engine in vehicles with space for it, with the aim of creating hybrid cars.

The ‘crate’ powertrain also has other advantages, such as it allows the inverter and cooling system to be flexibly positioned. Also, there is the possibility to fix the engine in different places. For all these reasons, it is easy to install, depending on the vehicle’s front or rear.

The engine is expected to go into production by June 2020, and the company will cover the validation costs of applying the engine to any vehicle, making it even more attractive to potential buyers.

It may be the solution that small brands and unconventional vehicles were waiting for.