Lithium-ion batteries use flammable materials and can cause battery fires by manufacturing errors. These batteries can contain thousands of tissue-paper thin folded sheets of porous plastic sheets.

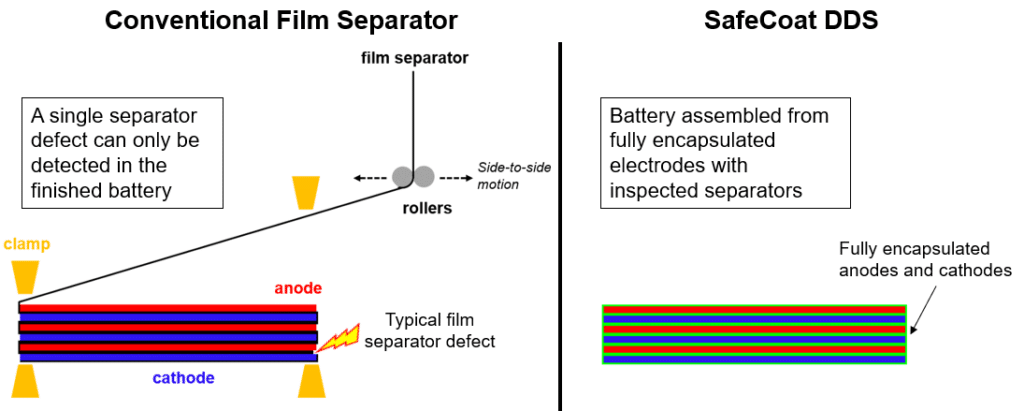

During the battery assembly, a single sheet separator can become damaged, creating undetectable wrinkles, misalignments, misfolding, or even small tears that can expose the electrodes to contact. These are the primary cause of battery defects creating internal shorts, thermal runaways, and battery fires.

To overcome this issue, an advanced battery materials startup, Nuvola Technology, announces its patented SafeCoat Direct Deposition Separator (DDS). This direct deposition polymer separator technology eliminates the primary cause of lithium-ion battery fires.

The Nuvola SafeCoat Direct Deposition Separator (DDS) is a solution for Lithium-ion batteries (LIB) that replaces conventional film separators with a porous polymer coating sprayed directly onto the entire electrode surface.

SafeCoat DDS is compatible with production techniques used in LIB factories worldwide. It replaces the troublesome plastic sheet separator materials used in today’s battery manufacturing processes.

It’s innovative spray-on coating completely shields and protects and ensures the electrodes never come into contact with thermal runaway and potential fire. This spray-on coating eliminates the primary cause of battery defects and manufacturing errors.

SafeCoat DDS technology can expect an energy density improvement of up to 20% in the same physical space by decreasing the thickness of the separator. The plastic separator film’s thickness is 20µm to SafeCoat’s ultra-thin 5µm layer leaves more room for active material without sacrificing battery performance.

“Improving battery safety is one of the highest priorities for the EV market, with large, energy-dense batteries representing a significant threat to public safety in the event of a fire,” said James Hodgson, Research Director, Automotive at ABI Research. “Nuvola Technology’s approach of separator coating offers the opportunity to improve both safety and production yield by modifying one step of the manufacturing process.”

The Nuvola SafeCoat product is now being evaluated by several major battery and car manufacturers, with products using the technology expected to be on the market in 2025.