Researchers at ETH Zurich have made significant progress in the development of such zinc batteries, making them more powerful, safer, and more environmentally friendly.

Currently, lithium-ion batteries are commonly used to power our smartphones, computers, and electric cars. But these batteries are highly flammable, and their relatively high cost, as well as projected supply shortages for lithium, make them suboptimal for grid storage.

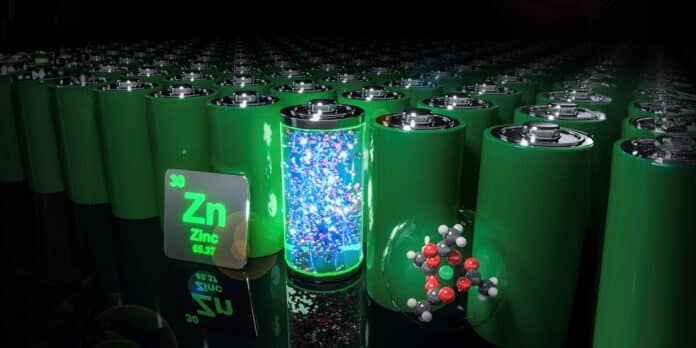

Rechargeable aqueous Zinc batteries offer a promising alternative for grid energy storage due to their high energy density, low cost, and non-flammability. Also, Zinc is abundant, cheap, and has a mature recycling infrastructure.

However, engineers have faced some challenges in developing these batteries. For example, when zinc batteries are charged at high voltage, the water in electrolyte fluid reacts on one of the electrodes to form hydrogen gas. This reaction causes the electrolyte fluid to dwindle and battery performance to decrease. Also, it causes excess pressure to build up in the battery, which can be dangerous. Another major problem for Zn metal anodes is dendrite formation during plating, which can lead to short-circuiting of the cells.

In recent years, engineers have enriched the aqueous liquid electrolyte with salts to address these issues. But it makes the electrolyte fluid viscous, which slows down the charging and discharging processes considerably. Additionally, many of the salts used contain fluorine, which makes them toxic and harmful to the environment.

An international team of researchers led by ETH Zurich has now devised a strategy that brings key advances to the development of cheap, efficient, durable, safe, and environmentally friendly zinc metal batteries. They searched for the ideal salt concentration for water-based zinc-ion batteries. Their experiments showed that the ideal salt concentration is not, as was previously assumed, the highest one possible but a relatively low one: five to ten water molecules per salt’s positive ion.

Researchers didn’t use any environmentally harmful salts for their improvements. Instead, they used environmentally friendly salts of acetic acid called acetates.

“With an ideal concentration of acetates, we were able to minimize electrolyte depletion and prevent Zinc dendrites just as well as other scientists previously did with high concentrations of toxic salts,” says Dario Gomez Vazquez, a doctoral student in Lukatskaya’s group and lead author of the study. “Moreover, with our approach, the batteries can be charged and discharged much faster.”

The ETH researchers have so far tested their new battery strategy on a relatively small laboratory scale. In the next step, they are planning to scale up the approach and see if it can also be translated for large batteries. Researchers hope that these might one day be used as storage units in the power grid to compensate for fluctuations, say, or in the basements of single-family homes to allow solar power produced during the day to be used in the evening.

Some challenges remain to overcome before zinc batteries are ready for the market. “We showed that by tuning electrolyte composition, efficient charging of Zinc anodes can be enabled,” says ETH Professor Lukatskaya. “Going forward, however, performance cathode materials will have to be optimized as well to realize durable and efficient zinc batteries.”

Journal reference:

- Dario Gomez Vazquez, Travis P. Pollard, Julian Mars, Ji Mun Yoo, Hans-Georg Steinrück, Sharon E. Bone, Olga V. Safonova, Michael F. Toney, Oleg Borodinb and Maria R. Lukatskaya. Creating a water-in-salt-like environment using coordinating anions in non-concentrated aqueous electrolytes for efficient Zn batteries. Energy & Environmental Science, 2023; DOI: 10.1039/D3EE00205E